Project Description

Milling graphite electrodes with diamond wire saws

DRAMET diamond wire grinding machines milling and saw graphite electrodes into contours and 2D shapes.

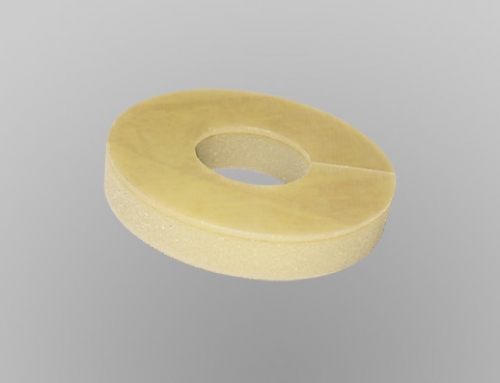

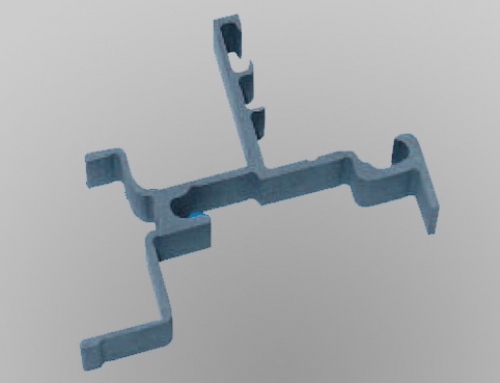

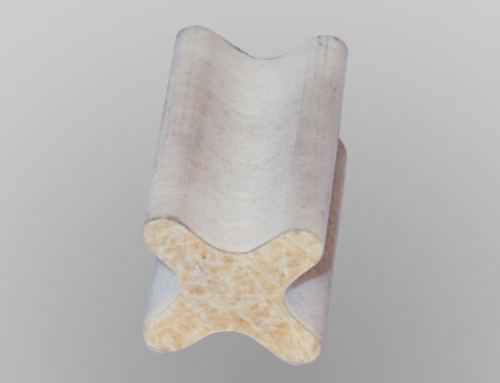

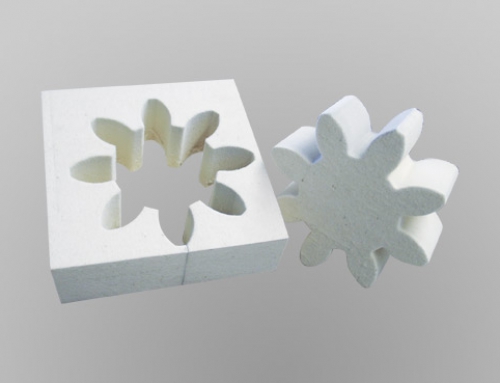

Materials such as graphite electrodes can thus be given individual shapes.

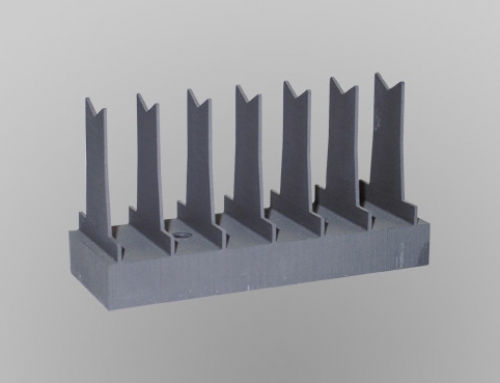

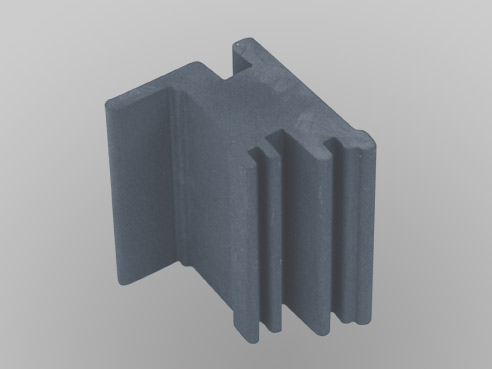

DRAMET diamond wire grinding machines saw graphite electrodes into contours as well as 2D and 3D shapes. Graphite electrodes are usually 30-100 mm high and require complex contours to be machined.

The difficulty often lies in the fact that only thin, widely projecting tools can be used for machining. A wire is the perfect tool for this, as it does not project, but is tensioned on both sides and very thin (approx. 1 mm).

This allows nested contours to be cut out of graphite plates accurately with little waste. With DRAMET solutions you not only achieve a surface quality comparable to grinding, you can also machine extremely thin strips without chipping.

Cutting graphite electrodes places particularly high demands on accuracy. Therefore, the diamond wire grinding machine DS 150 NC is equipped with very stable linear guidances and optionally with glass scales. This ensures precise contour guidance and best cutting results.