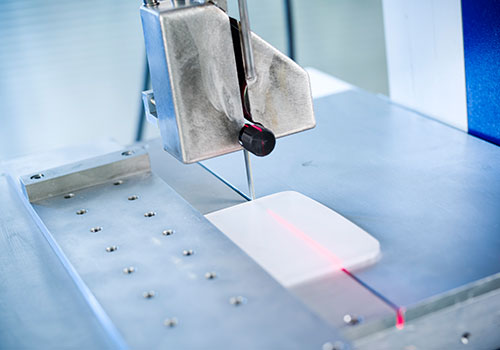

DRAMET concentrates on the specialized manufacture and development of diamond saws in special-purpose engineering

We build your individual diamond saw in our special-purpose engineering department

Wherever possible we attempt to meet your application tasks with our standardized machines and the customized equipment. Therefore DRAMET addresses the task by always implementing the most cost-effective solution.

We work hand in hand with our customers to find exactly the sawing device which complies with the specific tool geometry that our customers wish to mass produce.

We do much to comply with the requirements of your system. From the testing of sawing units and table devices, to the handling of the machine in the production process and the matching software programming.

DRAMET also takes care of your safety concept, which can include protection guards or splash guard cabins in compliance with the requirements in point.

The aim is always to comply with the time constraints and cycle times of our customers.

Your advantages?

Suitable extraction sockets are affixed in dry machining.

We find the optimal sawing solution for your mass production through intensive testing of the process, the cycle times and the cut results

The sawing process is then only perfect when the cut surface complies with the customer requirements. Tested are, for example, the saw surface and the saw tolerance. Does a band saw or a wire saw produce the optimal result or is a laser required? We test a variety of bands or wires in-house in order to achieve a faultless cutting result. Additionally we determine within the framework of the tests how the optimal handling should look on your unit. Our aim is to maintain the necessary cycle times, thus, in this context primary and secondary processing times are calculated.

Together with you we develop an optimal machine concept

It is determined how the machine is to be manufactured. The implementation for the later handling is of vital importance. How will the workpiece be held and placed into the machine? The customer requirements in relation to site, time and premises must be defined. Which options are needed in the framework of the automization technique and which software adaptations are required. How should the workpiece table be designed and how should the machine be driven. To this end the traveling axles are individually planned for you. An attachment to an existing assembly line may be of significance. In addition we must clarify which safety measures are required.

Construction, manufacture of individual parts, assembly and commissioning

The machines are constructed with the help of 3D CAD drawings and programs. Once the drawing has been drawn up, the machine is manufactured as a 3D model in order to send it to the customer for viewing. The parts are then manufactured in in-house production once the go-ahead has been given.

The parts are then put together and aligned in the assembly station. The machine is put into operation and run in as soon as it is completed.

As a rule our customers come to us for acceptance testing.