Project Description

Graphite sawing with diamond band saws

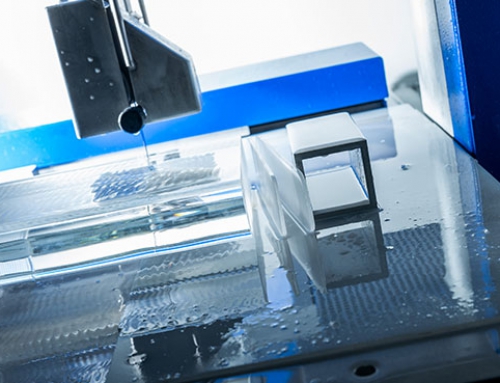

Sawing graphite with DRAMET diamond band saws

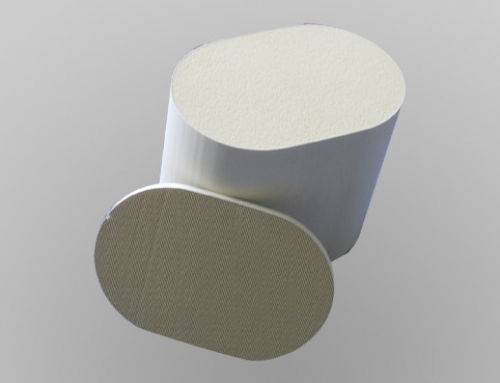

Graphite diamond band saws are ideal for machining graphite. A frequent application is the production of graphite electrodes blanks. Graphite diamond band saws offer various technical advantages when cutting graphite. In principle, diamond tools have a long service life. They are operated at high cutting speeds.

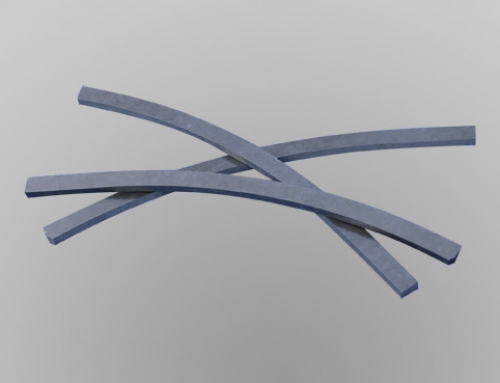

Dramet band saws work with cutting speeds between 1,000 and 3,000 m/min when cutting graphite. Graphite machining normally does not require a coolant and is thus performed dry. It would be technically correct to describe sawing with a graphite diamond band saw as a cut-off grinding process. As with grinding, the cutting edge is also undefined. This means that the sawn surfaces can also be compared with ground surfaces. The cuts are extremely precise, level and coplanar. Since Dramet uses with very thin bands (band thicknesses from 0.16 to 0.35 mm), the kerf is also very small. This results in various advantages:

• Less material loss leads to cost savings

• Less waste since less dust needs to be extracted

• Lower power consumption due to lower drive power

• Less temperature is introduced into the workpiece

• Lower sawing forces on the material require lower clamping forces

• Gentle material removal and low process forces prevent material flaking at the edges

Diamond grains D76 to D181 are used to achieve the very good surface qualities mentioned above. Common process parameters are a workpiece height of approx. 70 mm, a band speed of 1,700 m/min and a feed rate of 20 to 100 mm/min. The feed forces in this process remain very low at 0.5-4 N. These process parameters are used, for example, in the manufacture of precise graphite electrode blanks.

If productivity is more important, feed rates of 300-750 mm/min can be achieved with coarser diamond grains (D251-D356) and higher feed forces. This will result in inferior surface qualities and greater tolerances. The kerf and sawing forces will also be higher. However, significant economic advantages can be achieved this way compared to conventional graphite band saws. Diamond-studded saw bands are used which, despite a diamond grain of e.g. D301, only create kerfs of approx. 0.8 mm. In addition to the long tool life of the bands, this process also benefits from the above-mentioned advantages.

The diamond band saw has a wide range of applications in graphite machining. A suitable solution can be found for every application depending on the requirements.