Project Description

The diamond parting-off grinder DS150 NC is a modern production machine

The diamond wire saw DS150 NC is ideal for the cutting of 2D contours.

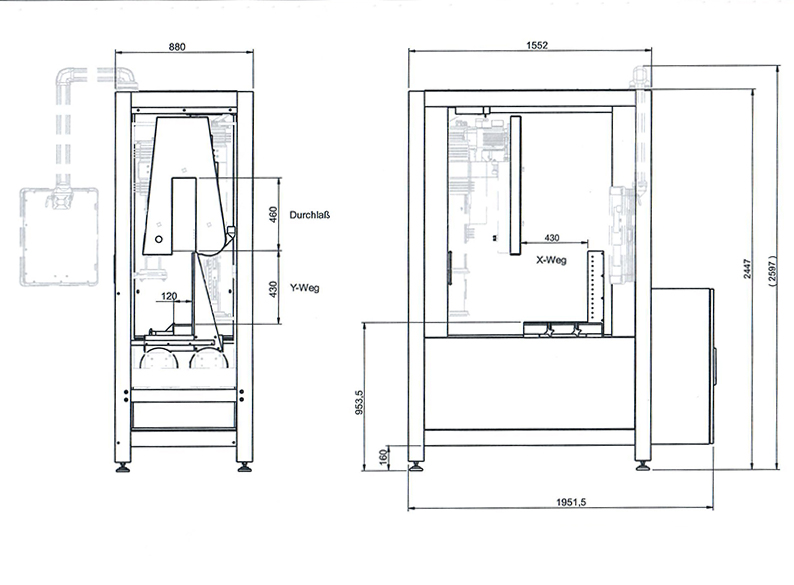

Passage (HxW) is 120 x 460 mm, travel work area is 430 x 430 mm (X axis, Y axis)

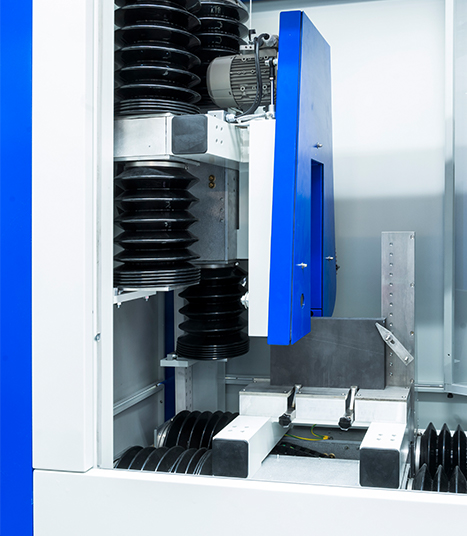

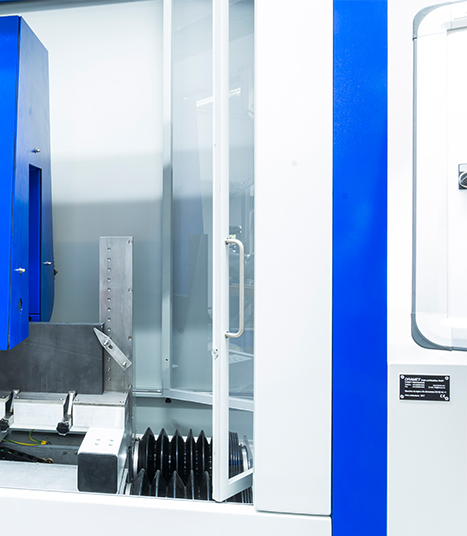

The diamond wire saw DS150 NC is a diamond parting-off grinder which lends itself ideally for the cutting of 2D contours. The wire unit works horizontal, therefore after cutting the workpiece remains at the starting material, it does not fall off. The linear guidings with recirculation ball bearings are covered by folding bellows. This guarantees a longevity when sawing abrasive materials.

The ball screws used for the feed allow the pre-programmed contour to be followed with high precision. The process of programming the workpiece contour with external CAD programs is supported by such features as automatic tool radius correction, automatic closure of the contour and the graphic display and process simulation.

The diamond wire saw DS150 NC saws 2D contours in a variety of materials

- Ceramic green machining with diamond wire sawsMarco Ripanti2019-05-17T16:48:16+00:00

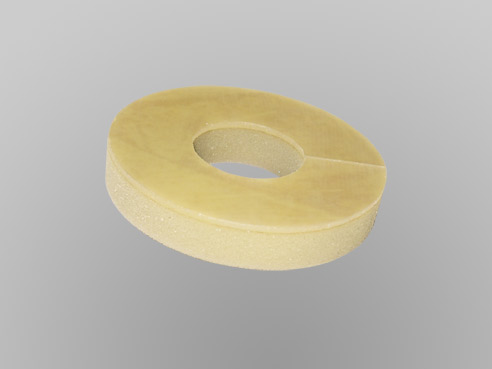

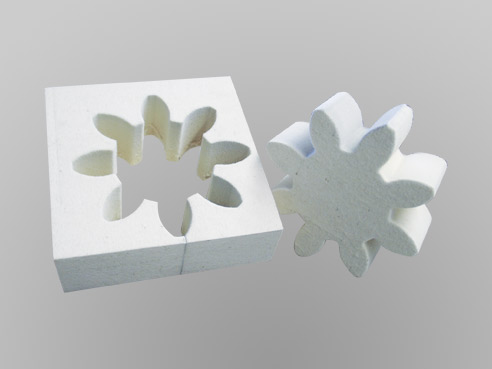

Ceramic green machining with diamond wire saws

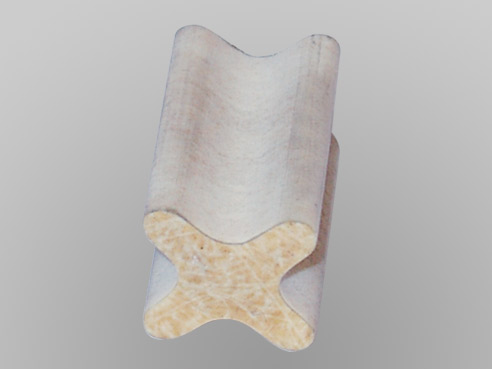

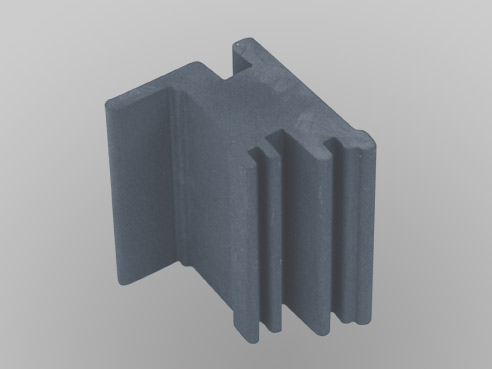

- Carbide green machining with diamond wire sawsMarco Ripanti2019-05-17T16:53:53+00:00

Carbide green machining with diamond wire saws

- Felt cutting with diamond wire sawsMarco Ripanti2019-05-17T17:48:17+00:00

Felt cutting with diamond wire saws

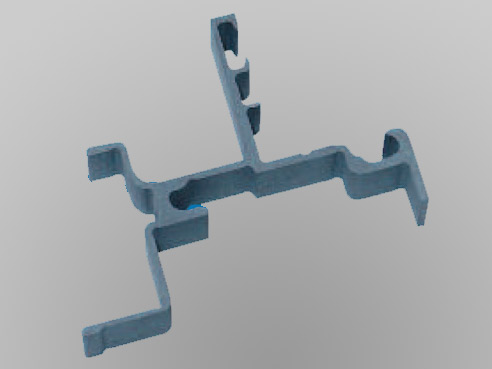

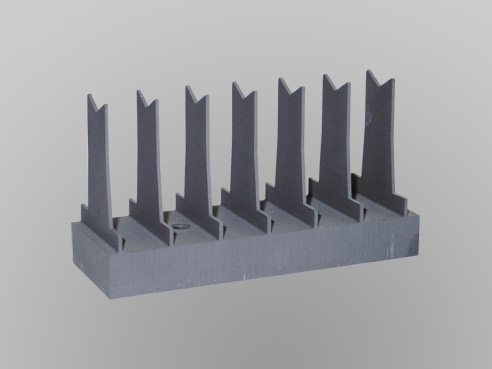

- Milling graphite electrodes with diamond wire sawsMarco Ripanti2019-05-17T17:54:59+00:00

Milling graphite electrodes with diamond wire saws

Weitere technische Details zur Diamantsäge DS150 NC

The process of programming the workpiece contour with external CAD programs is supported by such features as automatic tool radius correction, automatic closure of the contour and the graphic display and process simulation. Precision in following the contour is ensured by ball screws, which achieve an optimum result in combination with the automatic delay in movement when radii are being processed.

The machine is equipped with glass scales for precise table positioning.

The dust is extracted directly under the work area. The sawdust is pulled down by the wire and then directly extracted.

| Technical data | Description |

|---|---|

| Lenght: | 1968 mm |

| Width: | 880 – 890 mm |

| Height: | 2600 mm with a use panel |

| Passage: | 120 mm x 460 mm |

| Work area (X axis, Y axis): | 430 mm, 430 mm |

| Axes of rotation: | 150 mm |

| Sawing wire: | Ø 0,7 – 1,2 mm, Length 2100 mm |

| Wire speed: | 100 – 3000 m/min |

| Drive: | Three-phase current motor 750 W |

| Weight: | 600 kg |