Project Description

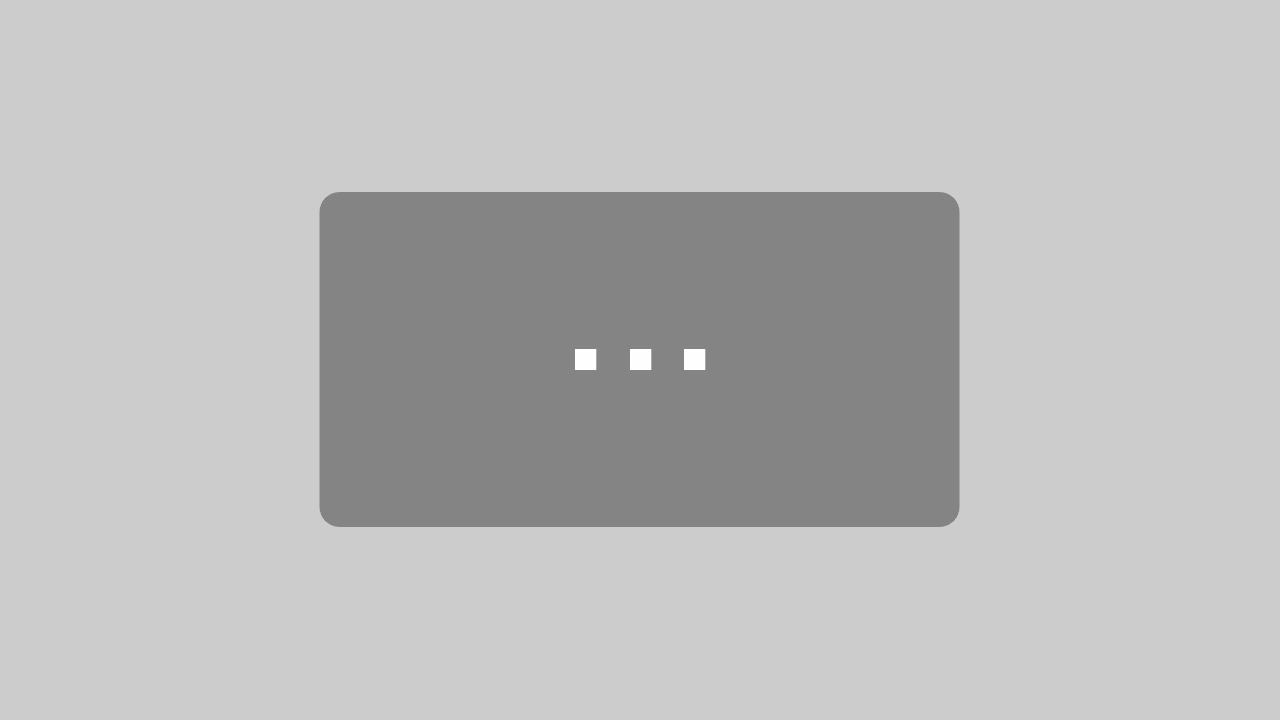

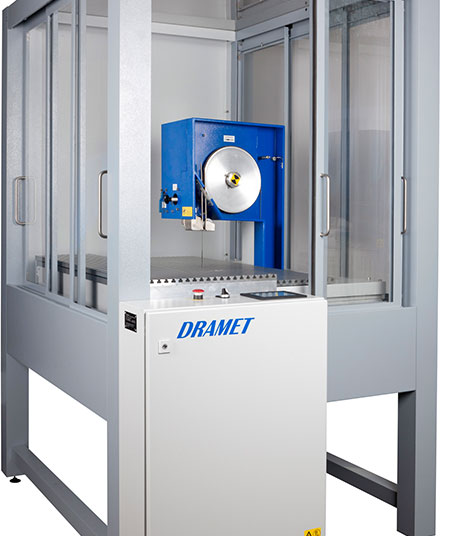

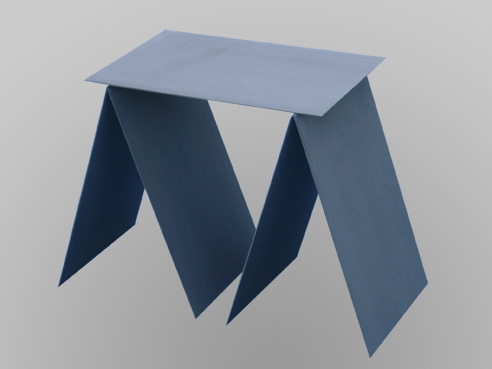

The diamond band saw BS270 F is also available in the version FY

The diamond band saw BS270 F/FY is a saw with a driven column

Passage(HxW) 180× 255 mm, cutting length (X-axis) is 600 mm.

The diamond band saw BS270 in its standard version 270F is a machine which is X-direction driven.

When equipped with an NC-driven 2-axis machine, it is available in the version BS270 FY.

Optionally the sawing forces can be used for feed regulation and shown on the display. The feed force occurring during sawing is shown on the display and feed as well as cutting speed can be manually tuned or regulated automatically in accordance with the programmable nominal force.

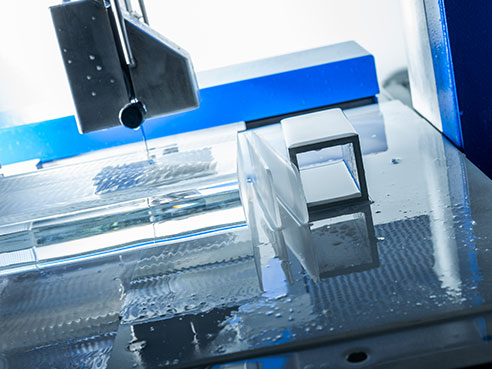

Both dry cutting and cutting with coolant are possible.

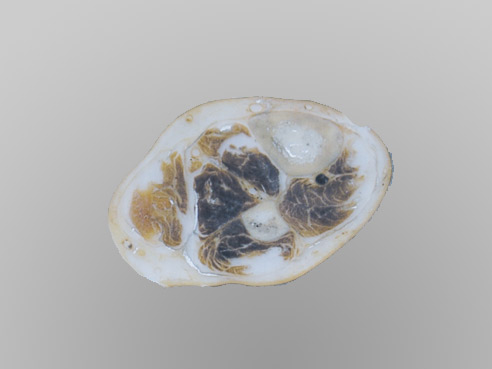

The diamond band saw BS270 F and FY are cutting various substrates

- Optical glass cutting with diamond band sawsMarco Ripanti2019-05-17T16:08:08+00:00

Optical glass cutting with diamond band saws

- Graphite sawing with diamond band sawsMarco Ripanti2019-05-09T15:06:30+00:00

Graphite sawing with diamond band saws

- GRP materials sawing with diamond band sawsMarco Ripanti2019-05-17T16:15:58+00:00

GRP materials sawing with diamond band saws

- Sawing industrial ceramics with diamond band sawsMarco Ripanti2019-05-17T16:20:19+00:00

Sawing industrial ceramics with diamond band saws

- Technical ceramic machining with diamond band sawsMarco Ripanti2019-05-17T16:26:16+00:00

Technical ceramic machining with diamond band saws

- Pathology Saw with diamond band sawMarco Ripanti2019-05-17T16:33:39+00:00

Pathology Saw with diamond band saw

More technical details concerning the Diamond band saw BS270 F and FY

The travel of the band unit is program-controlled with a ball screw and the servomotor (X axis). Travel and feed rates are programmable. The band unit can be positioned with the help of buttons. Control: Mitsubishi touch-screen PLC control. The BS270 F is upgraded to the CNC-controlled 2-axis BS270 FY by fitting it with a servomotor-driven Y table.

It can be operated with a dry cut or alternatively with cooling. For dry cutting, a suction unit is attached to the exhaust connector provided. For the stainless version, pure water can be used for cooling.

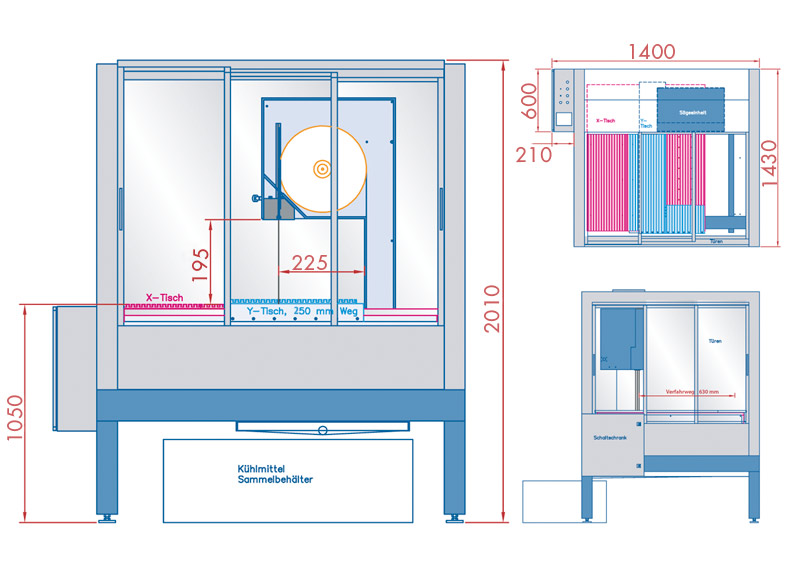

| Technical data | BS270 F with machine housing | BS270 F without machine housing |

|---|---|---|

| Length: | 1430 mm | 1230 mm |

| Width: | 1400 mm | 1200 mm |

| Hight: | 2100 mm | 1620 mm |

| Passage(H x W): | 180 mm x 255 mm | 180 mm x 255 mm |

| Travel (X, Y): | 630 mm, 250 mm | 630 mm, 250 mm |

| Deflection roller diameter Ø: | 266 mm | 266 mm |

| Guide roller diameter Ø: | 47 mm | 47 mm |

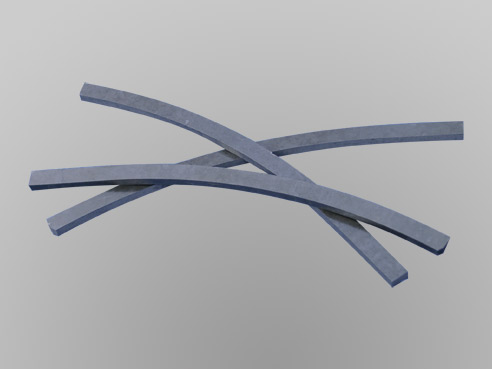

| Standard band: | 0,7 mm x 8 mm, length 1870 mm | 0,7 mm x 8 mm, length 1870 mm |

| Band speed: | 200 – 2000 m/min | 200 – 2000 m/min |

| Band tension: | 3.000 N | 3.000 N |

| Drive: | Three-phase current motor 750 W | Three-phase current motor 750 W |

| Weight: | 310 kg | 220 kg |

Measuring unit to measure feed force

During cutting, the feed force is displayed on the screen. This allows the feed and band speed to be optimally adjusted.

Band cleaning

The band is cleaned by a set of high-pressure spray pipes. Because the saw band is cleaned under high pressure under the work area, the band returns to the cut completely clean.

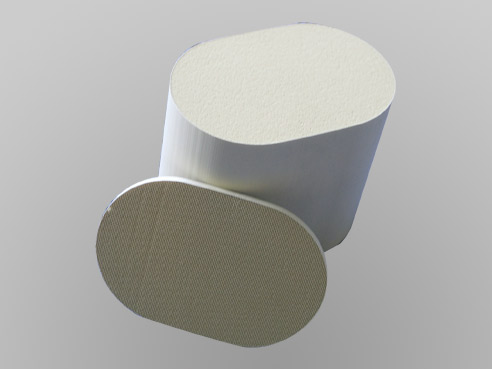

Coolant system with filter insert

Collecting tray with drain to coolant tank, coolant pump, coolant supply with shut-off valve and articulated pipe, automatic control of coolant system. A filter tissue of around 0.7 x 0.7 m can be inserted and replaced when necessary.

Spray protection cabin

Machine housing with Perspex® insert to protect against spray