Graphite and specialty graphite are among the most fascinating materials in industry – and among the most demanding when it comes to processing.

Their potential is enormous: from semiconductor manufacturing to high-temperature processes, battery technologies, and hydrogen applications.

But these strengths come at a price: graphite is brittle, generates abrasive fine dust, and is highly sensitive to mechanical stress.

Anyone aiming for reproducible dimensional accuracy in the hundredth-millimeter range must rely on specially adapted machine technology. Standard saws or milling machines quickly reach their limits – leading to excessive tool wear, chipping at the cut edge, or unnecessary material loss.

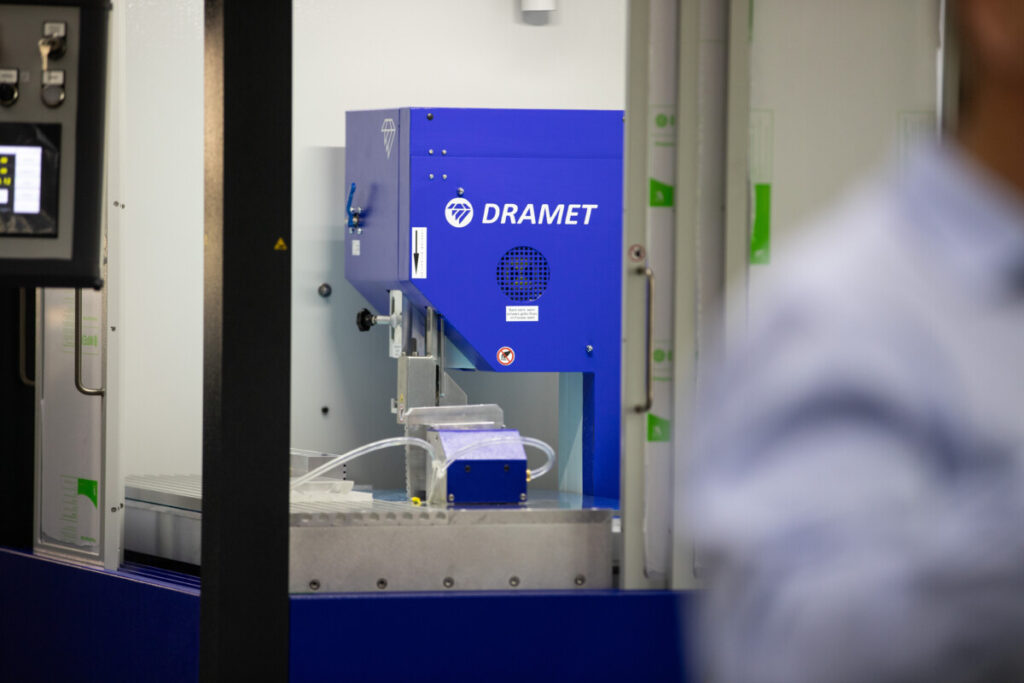

This is where DRAMET comes in: with over 30 years of experience in the development of diamond band saws and diamond wire saws for precise industrial applications, we supply machines that produce clean, smooth cuts even on the most sensitive graphite components – economical, low-dust, and material-efficient.

Why Graphite Requires Specialized Processing

Graphite impresses in industry with its unique properties:

- Temperature resistance up to over 3000 °C (in protective atmosphere)

- High electrical and thermal conductivity

- Chemical resistance, even against aggressive media

- Low thermal expansion and excellent dimensional stability

These advantages can only be fully utilized when the material is processed precisely and gently.

Improper machining leads to chipping, dimensional inaccuracies, or unnecessary material loss – exactly where Dramet provides the solution.

Machine Series for Graphite Processing

200 Series – Compact Precision for Laboratory & Prototyping

- Cutting clearance: 200 × 200 mm

- Compact design, ideal for research facilities and small series production

- Integrated extraction channel

- Options: stainless steel design, inclined worktable, line laser, protective enclosure, and water cooling

270 Series – Flexible and Automatable

- Cutting clearance: 180 × 255 mm

- Movable saw unit, freely traversable X & Y axes

- NC control for reproducible cuts

- Process monitoring via cutting force measurement

- Options: water cooling, line laser, reinforced main drive motor for higher torque, protective enclosure with safety interlock

400 Series – Large, Robust, Powerful

- Cutting clearance: up to 600 × 410 mm

- For massive workpieces and high material thicknesses

- NC control and T-slot tables for flexible clamping options

- Options: stainless steel design, enclosed axis systems, water cooling, reinforced main drive motor for higher torque, protective enclosure with safety interlock

Conclusion

Graphite is a key material for future technologies – but its processing is a precision task.

With DRAMET diamond band saws you secure:

Maximum dimensional accuracy

Material conservation

Process reliability – from single-piece to series production

Contact us for a non-binding consultation about your application – and experience how precise, economical, and clean graphite processing can be.