- Diamond Band Saw BS230 XY

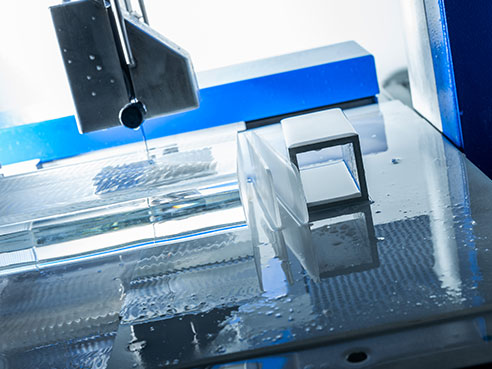

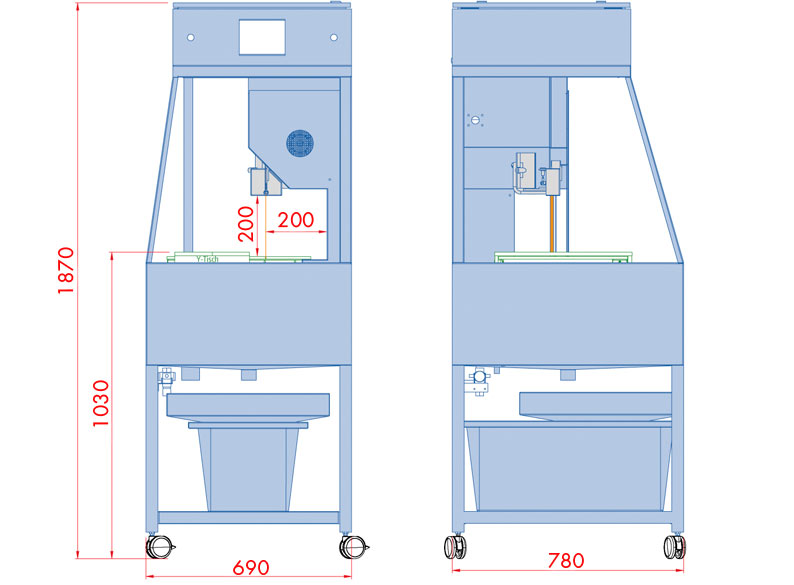

The BS230 XY is a compact, powerful laboratory saw with a standing saw unit. It offers a clearance of 200 x 200 mm (H x W), a cutting length of 200 mm (X-axis) and a footprint of 690 x 780 mm at a height of 1850 mm.

The workpiece is guided on a precise cross table with servo motor drive – both for the sawing process and for setting the slice thickness. The integrated display shows the sawing forces in real time, which are automatically used to regulate the feed speed. This corresponds to the speed at which the tool removes the material during sawing.

The BS230 XY is equipped as standard with a closed safety cabin and an integrated measuring unit for feed force control.

The machine enables dry cuts, but can also be operated with cooling as an option – depending on the requirements and material.

The BS230 XY diamond band saw cuts different materials

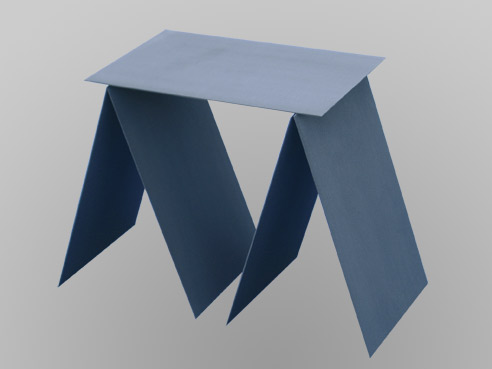

Optical glass cutting with diamond band saws

Materials for diamond band saws, glass sawing, cutting, abrasive cutting

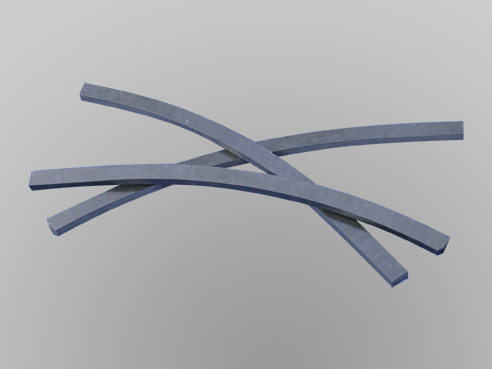

GRP sawing with diamond band saws

Materials for diamond band saws, cutting CFRP

Sawing graphite with diamond band saws

Materials for diamond band saws, graphite cut-off grinding

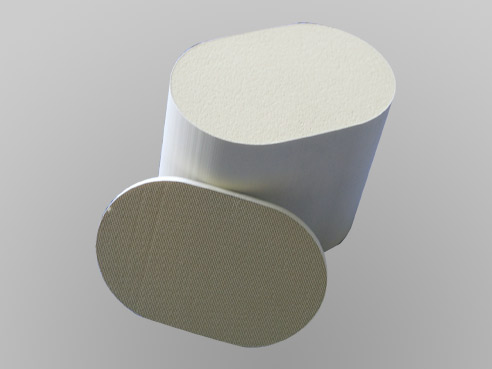

Cutting industrial ceramics with diamond band saws

Materials for diamond band saws, sawing glass, cutting, grinding

Technical ceramics processing with diamond band saws

Technical ceramics processing with diamond band saws

Pathology saw with diamond band

Materials for diamond band saws, sawing, cutting, grinding, and preparing plastinates

Further technical details on the BS230 XY diamond saw

The diamond saw blade of the BS230 XY runs endlessly over two rollers: It is driven by the upper roller and tensioned pneumatically. The tension can be precisely regulated by adjusting the air pressure on the pressure reducer. Two backlash-free guide roller units, which guide the band close to the processing point, ensure maximum cutting accuracy.

The drive is provided by a frequency-controlled three-phase motor, which enables a continuously adjustable belt speed of 200 to 2000 m/min.

The X and Y tables are equipped with ball screws and can be moved programmably by servomotors. Both travel distances and feed speeds are programmable; in addition, the tables can be positioned manually by pushbutton. They are controlled by a Mitsubishi PLC with touchscreen and menu-guided programming.

The machine is suitable for both dry cutting and operation with cooling. For dry cutting, an extraction system can be connected via the connection piece provided. The stainless steel machine version also allows the use of pure water without additives for cooling.

The BS230 XY is equipped with a measuring unit for feed force measurement as standard. The force generated during the sawing process is displayed directly on the screen – this allows the feed rate and cutting speed to be optimally adjusted.

To protect against spray water, a closed spray protection cabin is part of the machine’s standard equipment.

| Technical Data | Description |

|---|---|

| Length: | 780 mm |

| Width: | 690 mm |

| Height: | 1890 mm |

| Passage: | 200 mm x 200 mm |

| Travel (X, Y): | 200 mm, 200 mm |

| Deflection Rollers Ø: | 230 mm |

| Guide Rollers Ø: | 47 mm |

| Standard Belt: | 0,7 mm x 8 mm, Length 1870 mm |

| Belt Speed: | 200 – 2000 m/min |

| Belt Tension: | 2.000 N |

| Drive: | Three-Phase Motor 750 W |

| Weight: | 150 kg |

Additional Options

Coolant system with filter insert

Collecting tray, coolant filter, coolant pump, coolant supply with stopcock, automatic control of the coolant pump. A filter fleece measuring approx. 0.7 x 0.7 m can be inserted and replaced as required.

NIRO version, stainless steel version

Support and plates of the machine and the coolant system made of aluminum, shafts and bearings made of stainless steel. With this design, pure water can be used without additives.

Additional Options

Coolant system with filter insert

Collecting tray, coolant filter, coolant pump, coolant supply with stopcock, automatic control of the coolant pump. A filter fleece measuring approx. 0.7 x 0.7 m can be inserted and replaced as required.

NIRO version, stainless steel version

Support and plates of the machine and the coolant system made of aluminum, shafts and bearings made of stainless steel. With this design, pure water can be used without additives.