High energy prices are no longer a short-term exception but a new reality for industrial manufacturing companies. At the same time, demands for quality, delivery reliability, and sustainability continue to rise. In this environment, processes that were once underestimated are coming into focus—particularly cutting and separation processes. Here, efficiency plays a decisive role in overall competitiveness.

Why cutting processes consume more energy than expected

Cutting and grinding are energy-intensive process steps. High cutting forces, long machining times, and subsequent grinding or polishing operations further increase energy consumption. Especially when working with demanding materials such as graphite, ceramics, glass, or metals, inefficient processes have a direct impact on the overall energy balance.

Efficiency begins with precision

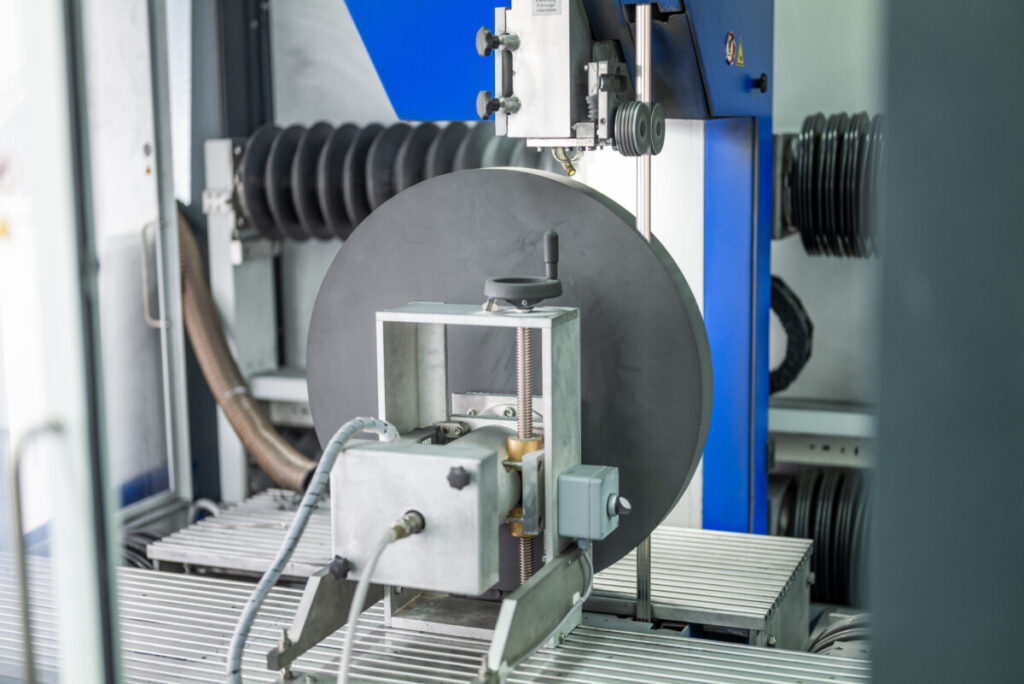

Efficient cutting processes are not achieved through maximum speed, but through controlled and precise operations. DRAMET diamond band saws operate with minimal cutting pressure and narrow kerfs. As a result, less energy is converted into friction and heat, and material removal is targeted and material-friendly. At the same time, the need for energy-intensive post-processing is reduced.

Less rework, less energy

Every additional grinding or polishing step significantly increases energy consumption. Precise cuts with smooth, even surfaces reduce or eliminate these steps entirely. In practice, this means shorter process chains, reduced machine operating times, and measurably lower energy consumption per component.

Stable processes permanently reduce consumption

Unstable processes not only generate scrap but also waste energy. Repeated cuts, corrections, and rework increase power consumption without adding value. Through reproducible cutting processes, NC control, and optional process monitoring, DRAMET ensures consistent results—and therefore sustainably lower energy usage.

Economic advantage through efficiency

In times of high energy prices, competitiveness is determined not only by material costs, but by the energy consumption per component. Companies that optimize their cutting processes can stabilize costs, improve pricing reliability, and reduce their exposure to energy price fluctuations. Efficient cutting technology thus becomes a strategic advantage.

Conclusion

While high energy prices cannot be controlled, the efficiency of internal processes can. Companies that rely on precise, stable, and energy-efficient cutting processes reduce costs, minimize rework, and strengthen their competitive position sustainably. DRAMET supports this goal with cutting technology that intelligently combines precision and efficiency.

Contact us for a non-binding consultation on how efficient cutting processes can sustainably reduce your energy costs.