Cutting Pressure – A Key Factor in Precision Machining

Cutting pressure is one of the decisive factors in precision machining. It describes the force with which the saw band or wire acts on the workpiece. Even small deviations can have major effects on quality, tool life, and material utilization.

Excessive Cutting Pressure – The Risks

• Chipping or cracking in brittle materials such as glass, ceramics, or graphite

• Dimensional deviations due to material deformation

• Increased heat generation and thermal stresses

• Faster wear of the saw band

Minimal Cutting Pressure – The Advantages

With optimized machine and tool technology, cutting pressure can be reduced to just a few newtons (typically 0.5–4 N on DRAMET machines). This ensures:

• Gentle processing of sensitive materials

• Highest dimensional accuracy, even for delicate workpieces

• Longer tool life

• Smooth cutting surfaces without reworking

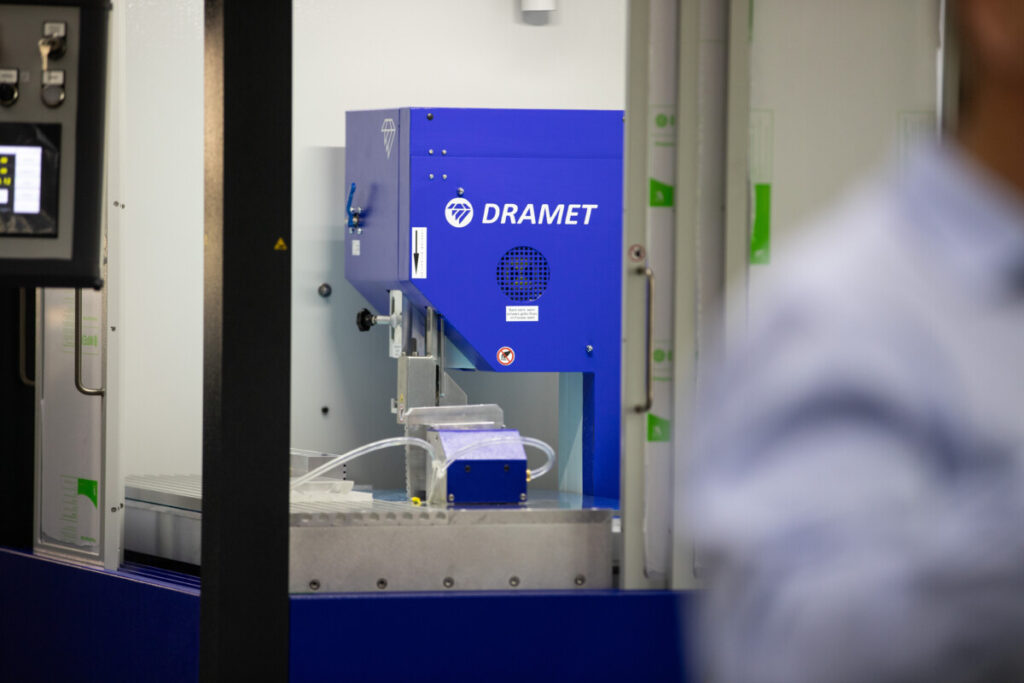

DRAMET Technology

Many of our diamond band saws are equipped with integrated cutting force measurement. This allows operators to monitor and precisely adjust the pressure in real time — a crucial advantage for repeatable precision.

Conclusion

Cutting pressure is not a minor detail but a central quality factor. Those who control it optimally can increase productivity, reduce costs, and improve cutting quality.

Contact us for a non-binding consultation on cutting parameters and measurement technology.