Material data sheets form the basis of many technical decisions. Hardness, density, flexural strength, or thermal conductivity provide important indications for machining a material. However, practical experience repeatedly shows that two materials with nearly identical specifications can behave completely differently during cutting. This is where pure theory reaches its limits.

Why data does not tell the whole story

Material data typically describes ideal conditions. It rarely accounts for real-world influencing factors such as material batches, internal stresses, porosity, fiber orientation, or inhomogeneous structures. Especially when working with sensitive and demanding materials such as graphite, technical ceramics, optical glass, or composite materials, these differences can lead to unexpected results—even when parameters appear to be “correct.”

Practice outweighs specifications

In precision machining, success is often determined not by what is written on the data sheet, but by how a material behaves under real cutting conditions. Cutting pressure, band grit size, clamping technique, and feed rate react sensitively to even minor variations in the material. These relationships cannot be fully calculated—they must be understood and experienced.

Experience as a guarantee of process reliability

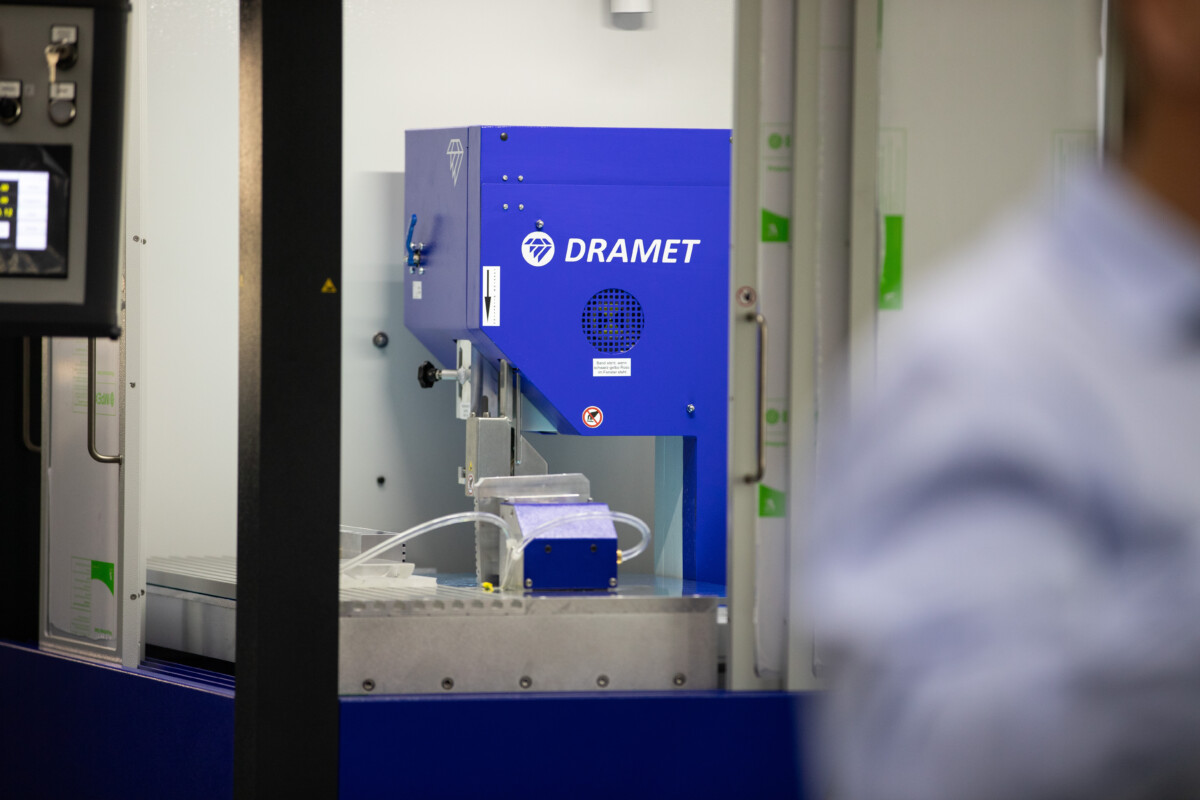

DRAMET brings decades of accumulated application expertise to every project. This knowledge is built on thousands of real cuts, tests, and customer applications. It becomes evident, for example, in knowing

• when a finer saw band provides more stability than reducing parameters

• how seemingly identical materials require different clamping strategies

• at what point a tool change is more effective than further parameter adjustments

This experience stabilizes processes—even where theory alone falls short.

Consulting as part of the solution

At DRAMET, expertise does not end with the machine. Application consulting, test cuts, and joint process design are integral parts of the overall concept. The goal is not merely to achieve a functioning cut, but to establish a reproducible and economically viable process. Particularly when dealing with new materials or unconventional applications, the combination of technology and experience is decisive.

From the first cut to series production

Experience-based processes are scalable. Companies that rely on solid know-how during the prototype or laboratory stage avoid costly surprises in series production. DRAMET supports customers along this path—from initial material testing to stable series manufacturing.

Conclusion

Material data is an important starting point—but it cannot replace experience. In precision machining of demanding materials, success depends on the interaction between technology, practical knowledge, and application expertise. DRAMET combines all these elements into solutions that do not just work in theory, but deliver reliable results in real-world production.

Contact us for a non-binding consultation if you prefer experience over trial and error when machining demanding materials.