When machining graphite, ceramics, glass, or CFRP & GFRP, fine abrasive particles and dust are generated.

These can not only endanger the operator’s health, but also impair machine precision and significantly increase wear.

The Challenge of Fine Dust

Health risk: Particles can enter the respiratory system

Machine wear: Dust clogs guides and bearings

Quality loss: Deposits on workpiece and tool affect dimensional accuracy

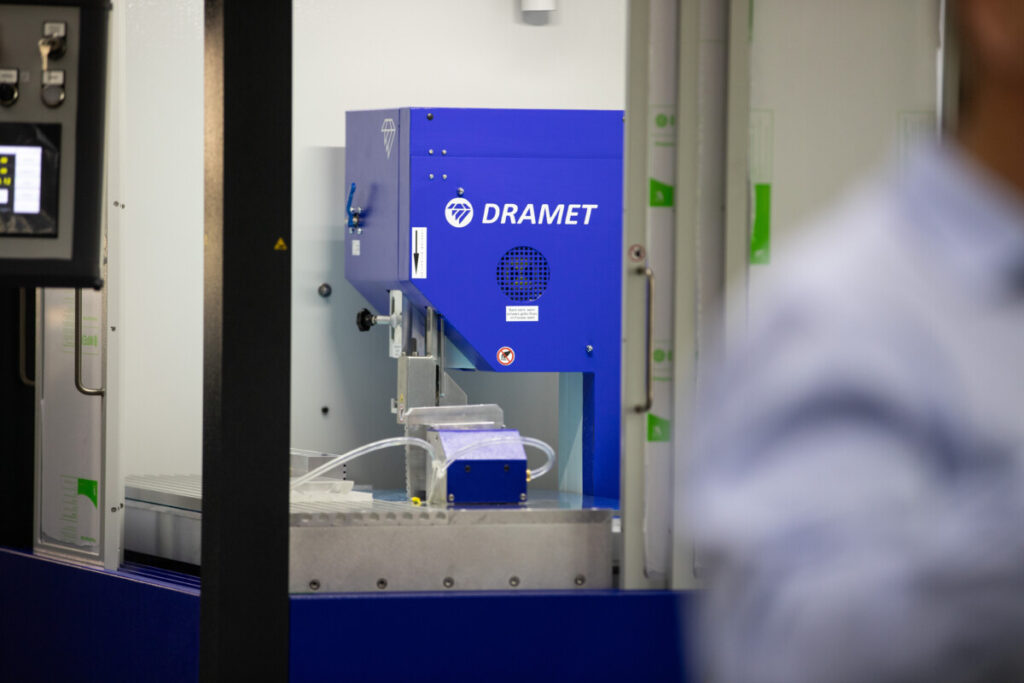

DRAMET Solutions for Clean Machining

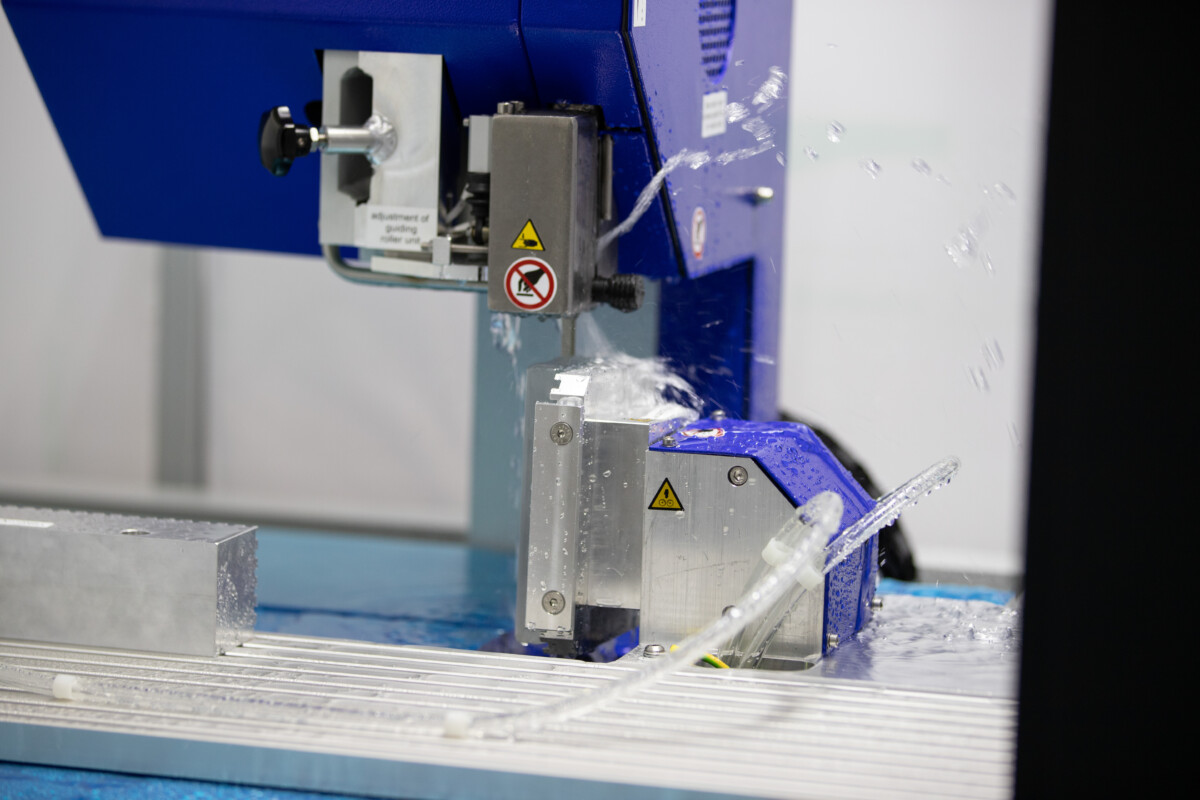

Our diamond band saws can be equipped with integrated extraction and/or water cooling – for maximum cleanliness and cutting quality.

Advantages of Water Cooling:

Binds dust directly at the cutting point

Reduces friction and heat generation

Extends the service life of saw bands

Advantages of Extraction:

Removes fine dust from the working area

Protects machine components from contamination

Provides clear visibility of the workpiece during cutting

Machines with Dust Protection Options

200 Series – compact, extraction channel standard, water cooling optional

270 Series – extraction channel standard, water cooling optional

400 Series – for large workpieces, low-dust machining even at high band speeds, extraction channel standard, water cooling optional

Conclusion

Clean machining is not only a matter of hygiene but directly linked to precision, tool life, and quality.

With DRAMET extraction and water cooling, you work safer, more efficiently, and extend the lifetime of your tools.

Contact us to learn how to keep your machining clean and process-safe.