In precision machining, the choice of cutting medium often determines the success or failure of a project.

Especially with hard, brittle, or abrasive materials such as graphite, technical ceramics, glass, or fiber-reinforced composites, conventional metal saw blades or carbide tools quickly reach their limits:

- High wear on hard surfaces

- Cracks or chipping in sensitive materials

- Poor cutting quality and extensive reworking requirements

The solution? Diamond-coated saw bands – in DRAMET’s specially developed grinding quality.

The Advantages of Diamond as a Cutting Medium

Diamond is the hardest known material and therefore capable of precisely cutting even extremely hard materials.

In combination with DRAMET’s highly flexible, endlessly closed saw bands, this results in advantages that make the difference in industrial applications:

- Maximum cutting precision – perfectly parallel cuts with tolerances down to 0.02 mm

- Smooth cut surfaces – often ready for use without reworking

- Minimal material loss – with kerfs as narrow as 0.45 mm

- Gentle processing – low cutting pressure (0.5–4 N) prevents material damage

- Universal application – suitable for brittle, hard, or abrasive materials

The Right Grit Size for Every Task

Depending on the material and desired surface quality, different grit sizes are available:

- Fine grit (76–126 µm) → highest surface quality, ideal for sensitive workpieces

- Medium grit (181 µm) → balanced compromise between cutting speed and quality

- Coarse grit (301 µm) → faster material removal for more robust materials

- Hybrid bands → combine different grit sizes on one band for maximum process efficiency

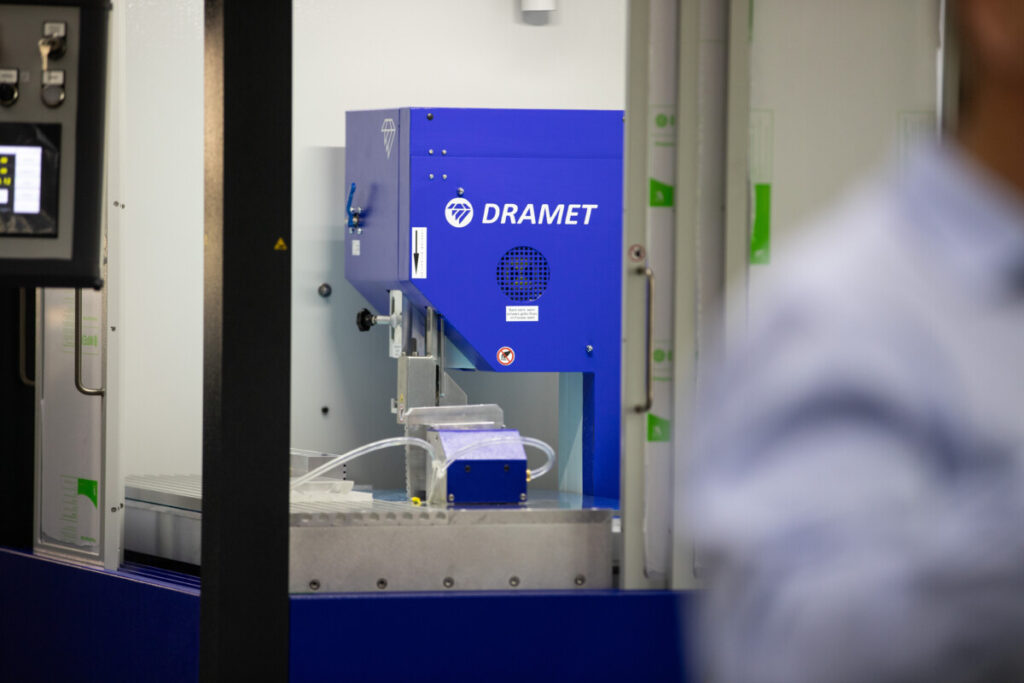

DRAMET Diamond Band Saws – Precision in Series

Since 1993, DRAMET has been developing machines perfectly adapted for the use of diamond-coated saw bands.

For every requirement, there is a suitable model:

- 200 Series – Compact, precise, and ideal for laboratory work, research, and small series production

- 270 Series – Flexible, automatable, and suitable for a wide variety of materials

- 400 Series – Large, robust, and powerful for massive workpieces and high material thicknesses

All models are available with NC control, integrated extraction, water cooling, and additional options – ensuring clean and repeatable cutting processes.

Conclusion

Diamond is not just a gemstone – it is the ultimate cutting medium for precision machining of demanding materials.

In combination with DRAMET diamond band saws, it delivers cutting qualities that conventional methods often cannot achieve – economical, reliable, and material-efficient.

Contact us and learn which machine and which saw band are the perfect fit for your application.