In many manufacturing processes, cutting a workpiece is inevitably followed by grinding – to achieve dimensional accuracy and surface quality. This costs time, increases production costs, and causes additional material loss. With DRAMET’s precise diamond band saws, this step can be combined into a single process.

Precision already at the cutting stage

Our diamond-coated saw bands with grinding quality deliver cut surfaces so smooth and flat that they can often be used without any further finishing. The kerfs are extremely narrow (down to 0.45 mm) and the cutting pressure is minimal, which reduces chipping or thermal damage to the material.

Advantages compared to conventional grinding

Significantly shorter process times

Less material loss thanks to narrow kerfs

Reduced tool and energy costs

Gentle machining of sensitive materials

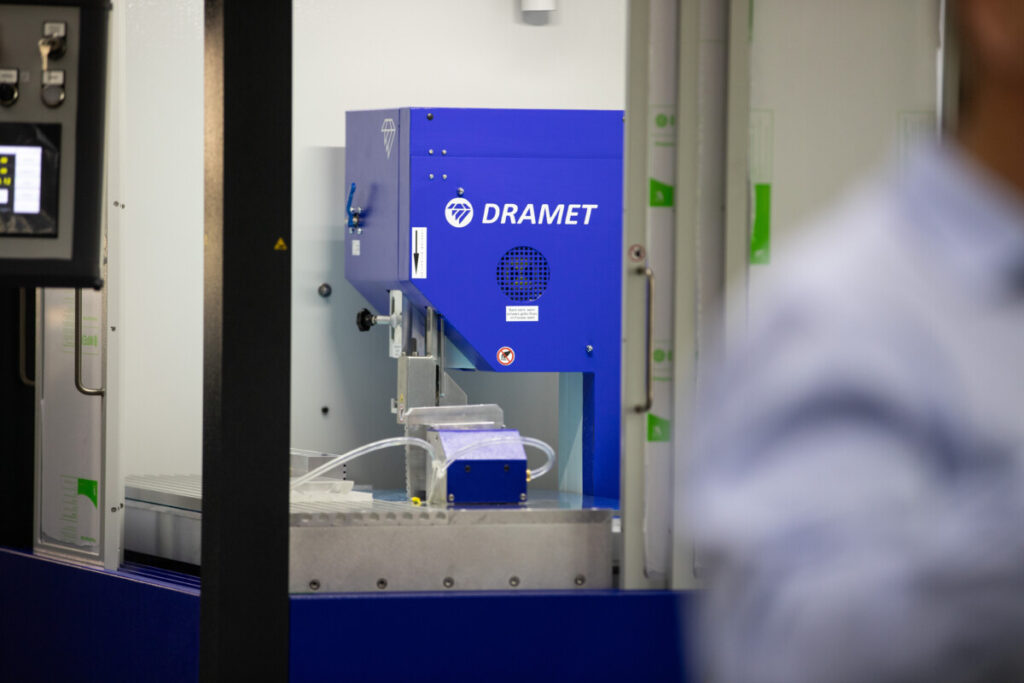

DRAMET machine solutions

200 Series – compact, precise, and ideal for small batches with high quality requirements

270 Series – flexible and automatable, perfect for medium production volumes

400 Series – robust and powerful for large workpieces and series production

Conclusion

With DRAMET diamond band saws, post-grinding can often be completely avoided. This means shorter lead times, lower costs, and better material utilization – with consistently high quality.

Contact us for a non-binding consultation on your production process.