Tight deadlines, short delivery times, and rising customer expectations shape today’s industrial environment. At the same time, quality, dimensional accuracy, and process reliability must not suffer. This tension reveals a crucial insight: it is not speed alone that shortens lead times, but above all stable processes.

Why time pressure amplifies unstable processes

In many production environments, time pressure is met by increasing feed rates or using more aggressive parameters. While this may appear to accelerate production in the short term, it often leads to higher scrap rates, increased rework, and machine downtime in the long run. Especially when machining sensitive materials such as graphite, ceramics, optical glass, or composite materials, unstable cutting processes quickly result in chipping, dimensional deviations, or tool-related issues. The consequence is delays instead of time savings.

Stable processes are faster than fast processes

A stable cutting process runs without interruptions. Parameters do not need constant readjustment, and workpieces do not require rework or remanufacturing. Reproducible cutting results ensure that every process step remains predictable—regardless of shift, operator, or batch size. This predictability is the key to short and reliable lead times.

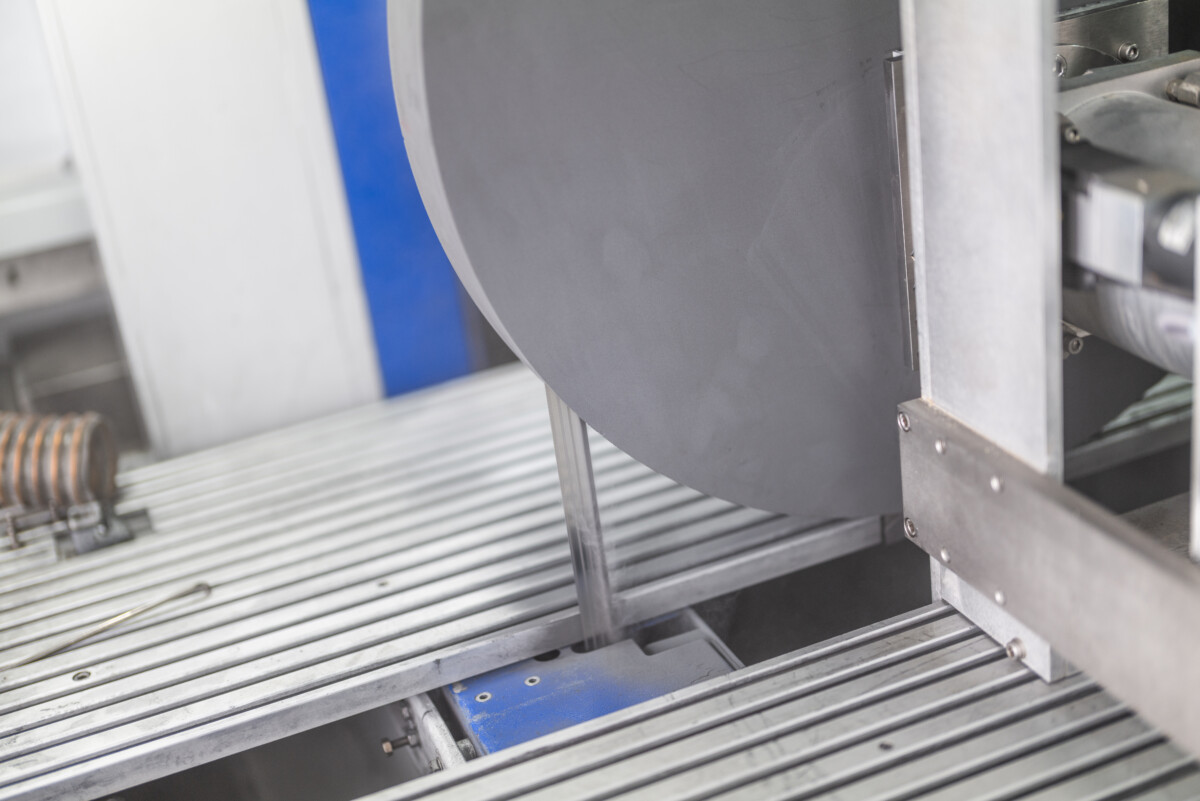

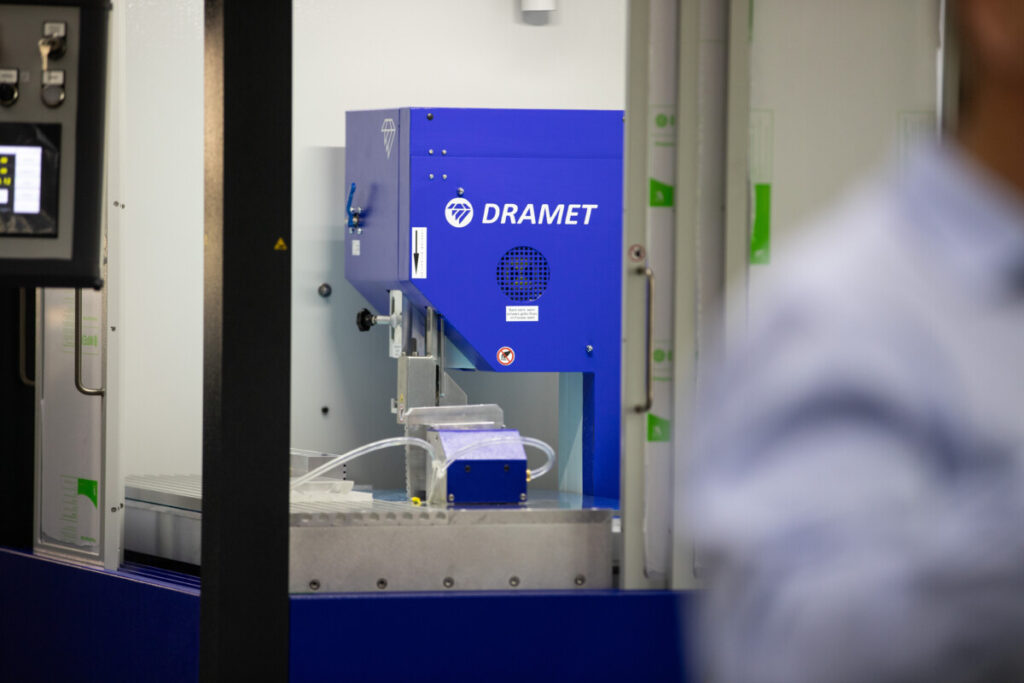

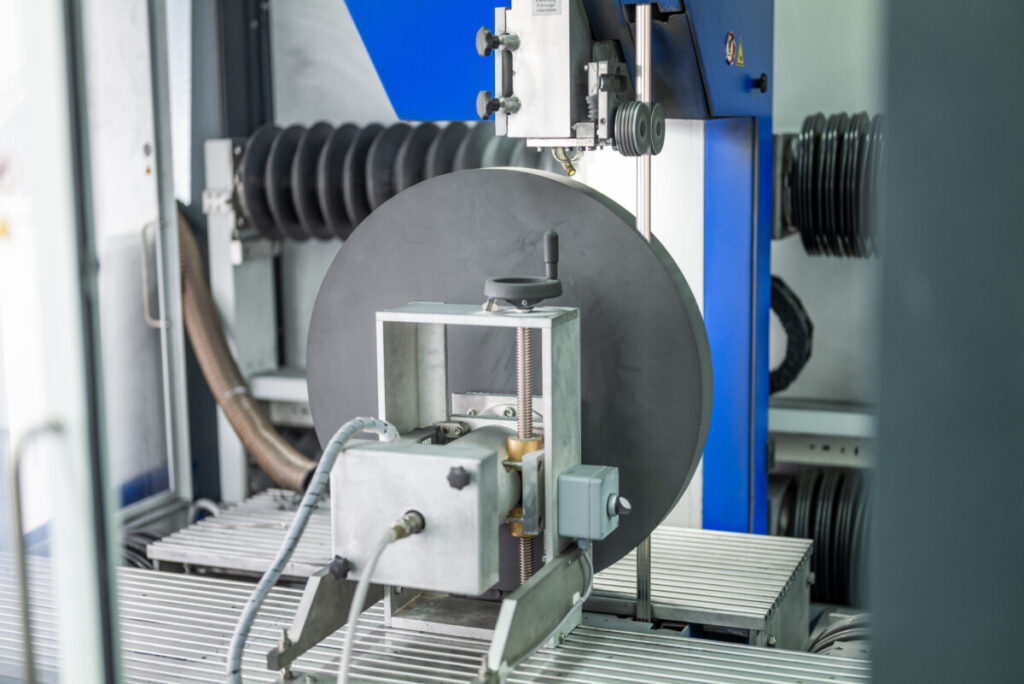

Technology that enables stability

DRAMET diamond band saws are designed for consistent process conditions. Precise band guidance, rigid machine structures, and optimally matched saw bands ensure uniform cutting quality. NC control systems enable reproducible motion sequences, while optional cutting force measurement detects deviations at an early stage. This allows processes to be controlled before instability occurs.

Fewer interventions, higher throughput

Stable processes reduce the need for manual intervention. Machines operate autonomously for longer periods, changeover times are reduced, and downtime is minimized. At the same time, tool life improves because saw bands are subjected to more uniform loads. The result is higher throughput with consistent quality—without additional pressure on operators or machines.

From prototype to series production without loss of time

Especially during the transition from development to series production, process stability determines the timeline. Achieving reproducible cuts already at the prototype stage saves valuable time during series ramp-up. DRAMET supports this transition with scalable machine concepts that apply the same process logic from single parts to automated series production.

Conclusion

Time pressure cannot be avoided—but process instability can. Companies that rely on stable cutting processes sustainably reduce lead times, minimize scrap, and relieve the burden on production. With precise machine technology, matched saw bands, and data-driven process control, DRAMET provides the foundation for fast, reliable, and predictable manufacturing processes.

Contact us for a non-binding consultation on how stable cutting processes can help reduce your lead times.