In precision machining, the focus is often on the machine, the cutting tool, and the cutting parameters. However, one decisive factor is frequently underestimated: workpiece clamping. True precision does not begin at the saw band—it starts with the safe, material-appropriate fixation of the workpiece.

Why improper clamping prevents precision

Especially when working with sensitive materials such as optical glass, graphite, technical ceramics, or composite materials, unsuitable clamping can have serious consequences. Excessive clamping forces generate internal stresses that may lead to cracks, chipping, or dimensional deviations. Insufficient fixation, on the other hand, promotes vibrations and micro-movements during cutting—negatively affecting surface quality and dimensional accuracy.

Workpiece clamping as part of the process

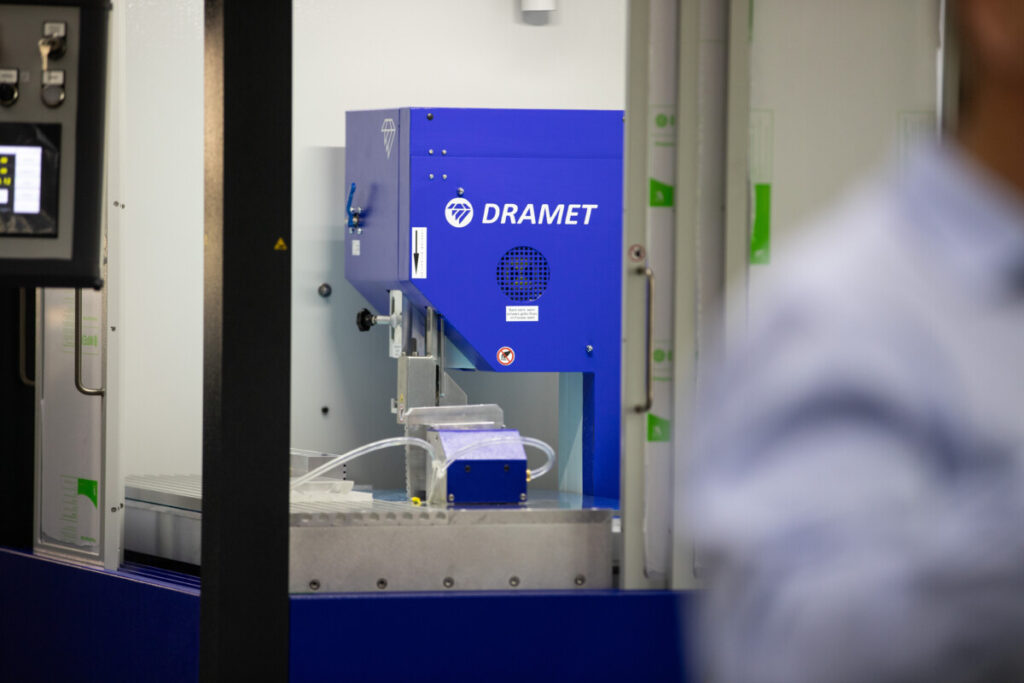

Precise workpiece clamping is not an accessory; it is an integral part of the entire cutting process. DRAMET therefore always considers clamping technology in conjunction with the machine, the saw band, and the process parameters. The goal is to secure the workpiece reliably without mechanically stressing or deforming it.

Special clamping solutions for demanding materials

Depending on material, geometry, and application, DRAMET develops customized clamping concepts. These include form-fit fixtures for sensitive glass geometries, surface clamping systems for uniform force distribution, and specially adapted devices for irregular or delicate components.

In combination with T-slot tables, finely adjustable clamping elements, and optional custom fixtures, these solutions enable reproducible cuts even on challenging workpieces.

Stable clamping – increased process reliability

A stable workpiece setup has a direct impact on process reliability. Reduced vibrations, uniform cutting pressure, and consistent cutting conditions lower scrap rates and tool wear. Especially in automated or NC-controlled processes, a reproducible clamping position is essential to ensure consistent results over many cycles.

From standard solutions to custom designs

While many applications can be covered with modular clamping systems, others require tailored solutions. In DRAMET’s custom machine engineering, clamping devices are precisely matched to the workpiece and the process—from the initial concept and design through to integration into the machine. The result is solutions that are not only precise, but also durable and practical for everyday use.

Conclusion

Precision begins with clamping. Those who treat workpiece clamping as a core element of the machining process reduce scrap, increase process stability, and achieve superior cutting results. DRAMET offers not only precise cutting technology, but also well-engineered clamping solutions—for reproducible quality from the first fixation to the final cut.

Contact us for a non-binding consultation on the optimal clamping solution for your application.