Metals such as tool steels, titanium, or nickel-based alloys place the highest demands on machining.

Their hardness and toughness cause high tool wear, heat generation, and often rough cut edges. Conventional sawing methods quickly reach their limits here.

The Solution: CBN Saw Bands from DRAMET

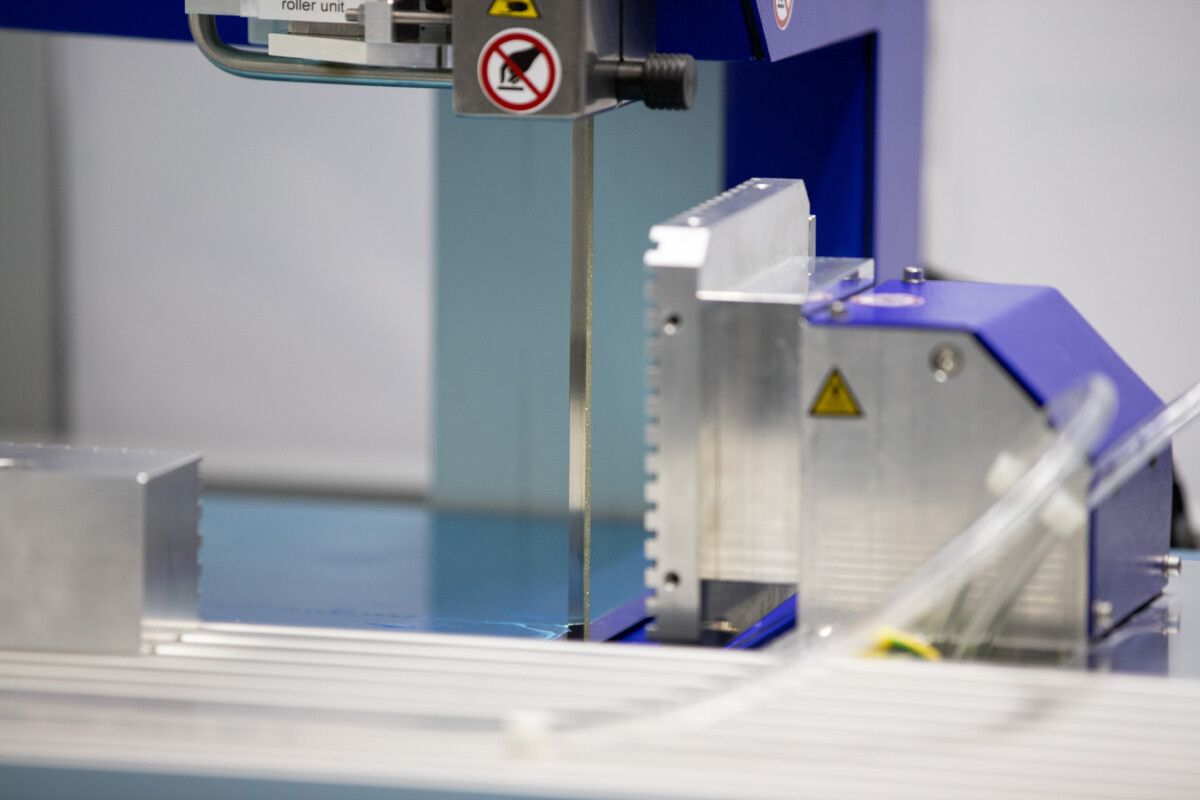

CBN (cubic boron nitride) is the second hardest known material after diamond – and is ideally suited for cut-off grinding of metals. Our CBN saw bands combine long service life with precise, clean cuts. They reduce burr formation, minimize material loss, and enable shorter machining times.

Advantages of CBN Technology

High temperature resistance – ideal for heat-sensitive metals

Lower tool wear compared to carbide or HSS

Precise, straight cuts even on large material thicknesses

Less reworking thanks to clean cut surfaces

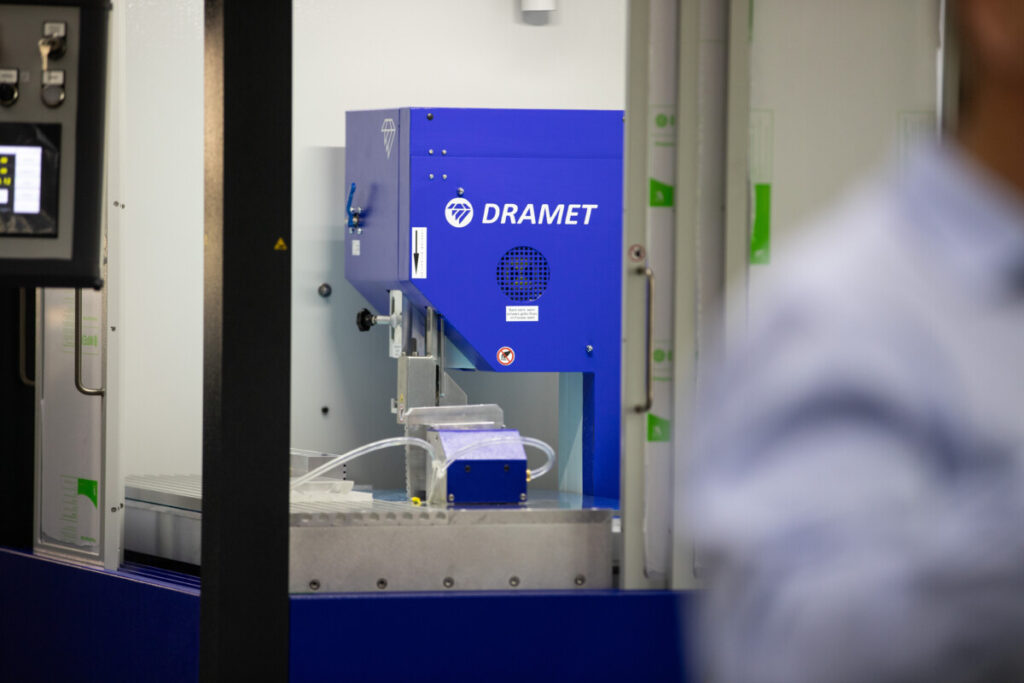

Suitable Machines

270 Series – flexible and automatable, ideal for medium-sized workpieces

400 Series – robust and powerful, also for large-format metal parts

Conclusion

With CBN saw bands and DRAMET diamond band saws, you can cut metals precisely, efficiently, and with minimal material waste – even with the most demanding alloys.

Contact us for a non-binding consultation on your metal machining needs.