When machining high-value materials such as graphite, ceramics, glass, or semiconductor materials, material waste is synonymous with increased costs. Wide kerfs mean more material removal – and less usable end product.

The Advantage of Narrow Kerfs

Our diamond-coated saw bands achieve kerf widths of just 0.45–0.9 mm. Compared to many conventional sawing methods, this is a significant reduction – with two decisive advantages:

More parts from the same raw material

Less waste and lower disposal costs

Practical Example

A graphite block with a height of 300 mm is cut into 30 plates. With a conventional kerf of 1 mm, 29 mm of material is lost solely due to cutting. With a DRAMET kerf of 0.45 mm, the loss is reduced to 13.05 mm – corresponding to a material saving of over 70%.

Machines for Maximum Material Utilization

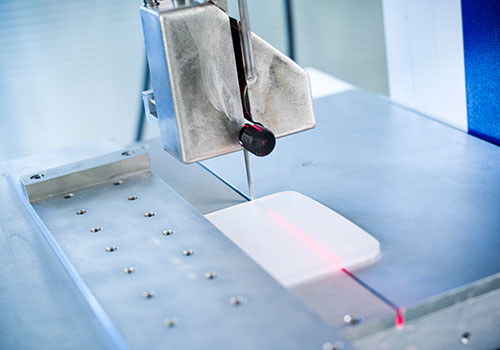

200 Series – ideal for fine cuts and laboratory applications

270 Series – flexible and automatable for series production

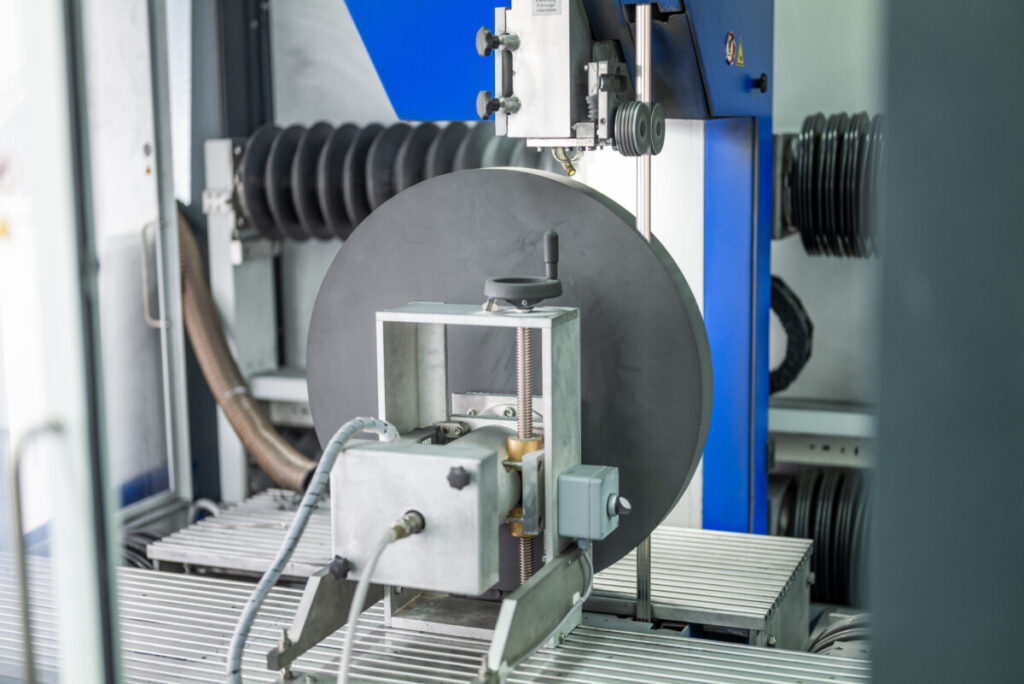

400 Series – robust and powerful for large workpieces

Conclusion

Precise, narrow kerfs reduce costs and increase yield. With DRAMET diamond band saws, you combine top cutting quality with maximum cost efficiency.

Contact us for a non-binding consultation on your application.