Technical ceramics are among the most powerful materials in modern industry.

They are used wherever components must be extremely wear-resistant, temperature-stable, or chemically resistant – often under conditions where metals quickly reach their limits.

Typical applications:

- Electronics & semiconductor technology – insulators, substrates

- Medical technology – surgical instruments, implants

- Mechanical engineering – wear-resistant bearings, seals

- Energy & environmental technology – high-temperature components, filter elements

Why machining is so challenging

Ceramics are hard, brittle, and sensitive to mechanical stress.

The greatest challenge: avoiding cracks and chipping while simultaneously ensuring the highest dimensional accuracy.

Conventional tools often result in:

- Chipping at the cut edges

- High reworking costs

- Short tool life

Diamond – the key to perfect cuts

The solution lies in diamond-coated saw bands, which DRAMET has been developing for more than 30 years.

Diamond is harder than any ceramic material and makes possible:

- Gentle machining with minimal cutting pressure

- Smooth, chip-free surfaces – often without reworking

- Extremely narrow kerfs

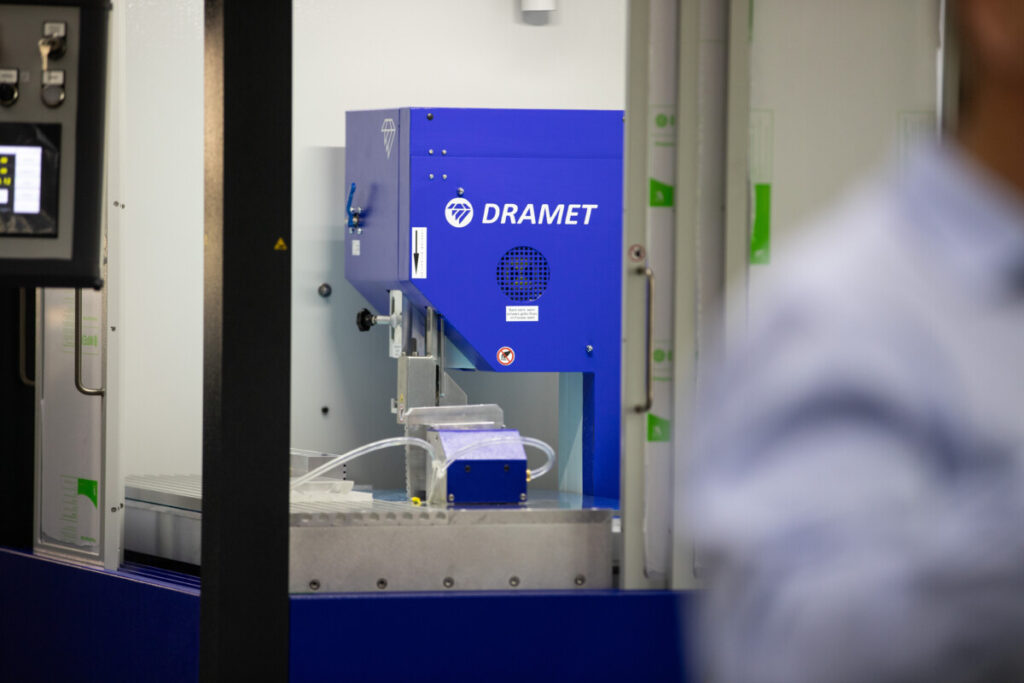

DRAMET machine solutions for technical ceramics

Depending on workpiece size and production volume, various diamond band saw series are available:

- 200 Series – Compact, precise, and perfect for laboratory and small-batch production.

With integrated water cooling and extraction for low-dust machining.

- 270 Series – Flexible and automatable, with a movable saw unit and NC control for repeatable cuts.

- 400 Series – Large-format and powerful, ideal for massive ceramic plates and components with high material thicknesses.

All machines can also be equipped with hybrid bands (different grits on a single band) for efficient processing of varying material thicknesses in one pass.

Conclusion

Technical ceramics place the highest demands on the machining process.

With DRAMET diamond band saws, you achieve precise, crack-free cuts, extend tool life, and reduce reworking – from prototype manufacturing to large-scale production.