When making investment decisions, the purchase price is often the first factor to come into focus. Especially for machines used in industrial manufacturing, it may appear at first glance to be the most important point of comparison. However, those who focus solely on the purchase price often overlook the decisive factor: lifecycle costs. Only these reveal how economical a machine truly is over many years—or even decades.

What lifecycle costs really mean

Total Cost of Ownership (TCO) includes far more than the initial purchase price. It encompasses energy consumption, tool and wear costs, maintenance, downtime, spare parts, post-processing, and scrap. Especially when machining high-value materials such as graphite, ceramics, glass, or semiconductor materials, even small inefficiencies can accumulate into significant costs over time.

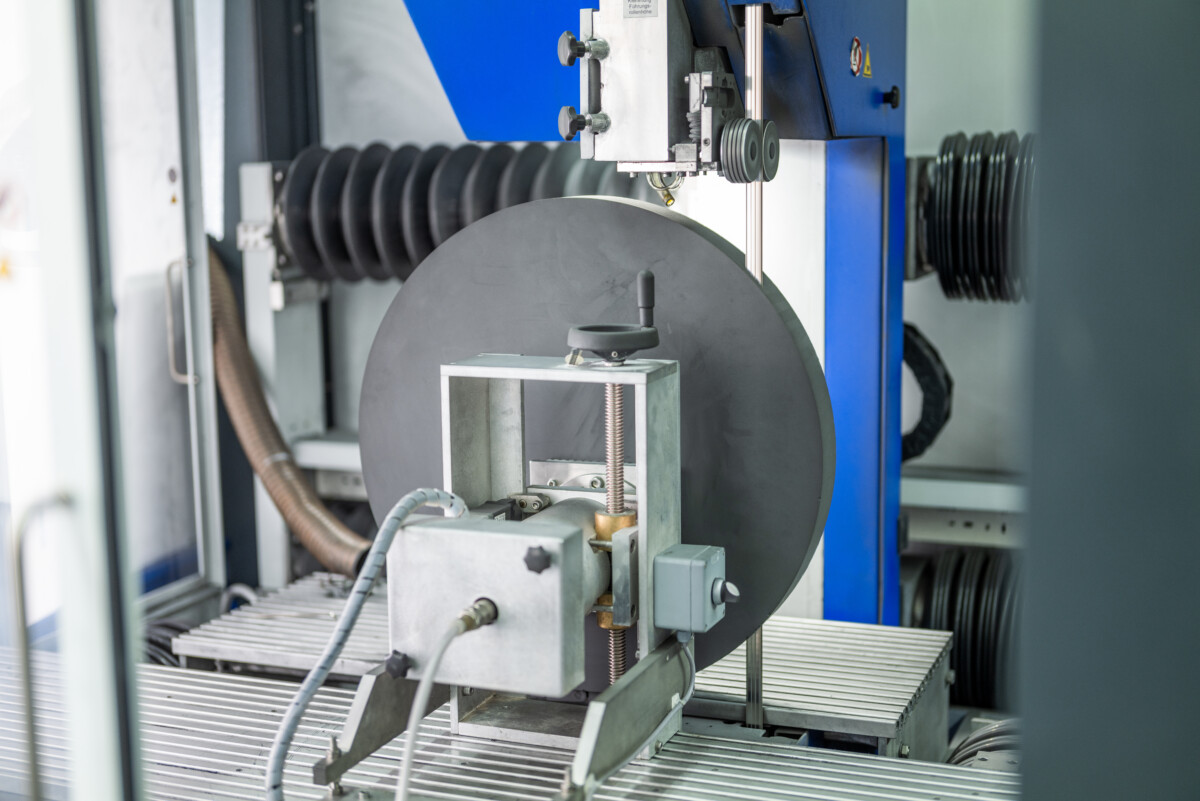

Precision reduces follow-up costs

DRAMET diamond band saws are designed for precise, stable processes. Narrow kerfs, low cutting pressure, and reproducible cutting results reduce material loss and rework. Less scrap not only lowers raw material costs but also reduces time spent in downstream process steps. Over the entire service life of the machine, these savings add up substantially.

Durability as an economic factor

A key contributor to low lifecycle costs is machine longevity. DRAMET manufactures machines in Germany with a high degree of in-house production. Robust designs, high-quality components, and maintenance-friendly construction ensure reliable operation even after many years of use. Instead of being replaced prematurely, DRAMET machines can be adapted to new requirements through modular options such as NC control, extraction systems, or water cooling.

Planned maintenance instead of unplanned downtime

Unplanned machine downtime is one of the biggest cost drivers in manufacturing. Thanks to stable mechanics, durable components, and reliable spare parts availability, DRAMET significantly reduces the risk of such failures. Maintenance can be planned, production interruptions minimized—creating security for production planning and delivery schedules.

Investment security over many years

Investment security is crucial, particularly in research, custom manufacturing, and industrial series production. A machine that delivers precise results today and remains expandable tomorrow protects against poor investments. DRAMET supports customers over the long term—not only with machines, but also with service, spare parts, and technical expertise throughout the entire lifecycle.

Conclusion

The purchase price is only part of the equation. When lifecycle costs are considered, it quickly becomes clear that quality, precision, and durability are the more economical choice. With DRAMET diamond band saws, companies invest in stable processes, lower follow-up costs, and long-term reliability—an investment that pays off over many years.

Contact us for a non-binding consultation on a cost-efficient and sustainable investment in your cutting processes.“