In many machining processes, workpieces are first roughly cut and then reworked with a finer grit.

In practice, this often means tool changes, additional clamping, and more machine time. With DRAMET hybrid saw bands, this intermediate step is no longer necessary.

What are hybrid saw bands?

Hybrid bands combine two different diamond grits on a single saw band. The front section handles fast rough cuts with high material removal, while the side sections with finer grit ensure a smooth, chip-free surface.

Key Advantages

Significantly shorter machining times by eliminating separate fine-cutting processes

Reduced tool changes and setup times

Minimized material loss thanks to narrow kerfs

Consistent cutting quality, even with varying material thicknesses

Perfect for demanding materials

Hybrid bands are especially suitable for materials such as graphite, technical ceramics, glass, and CFRP, where a combination of rapid material removal and perfect surface finish is required.

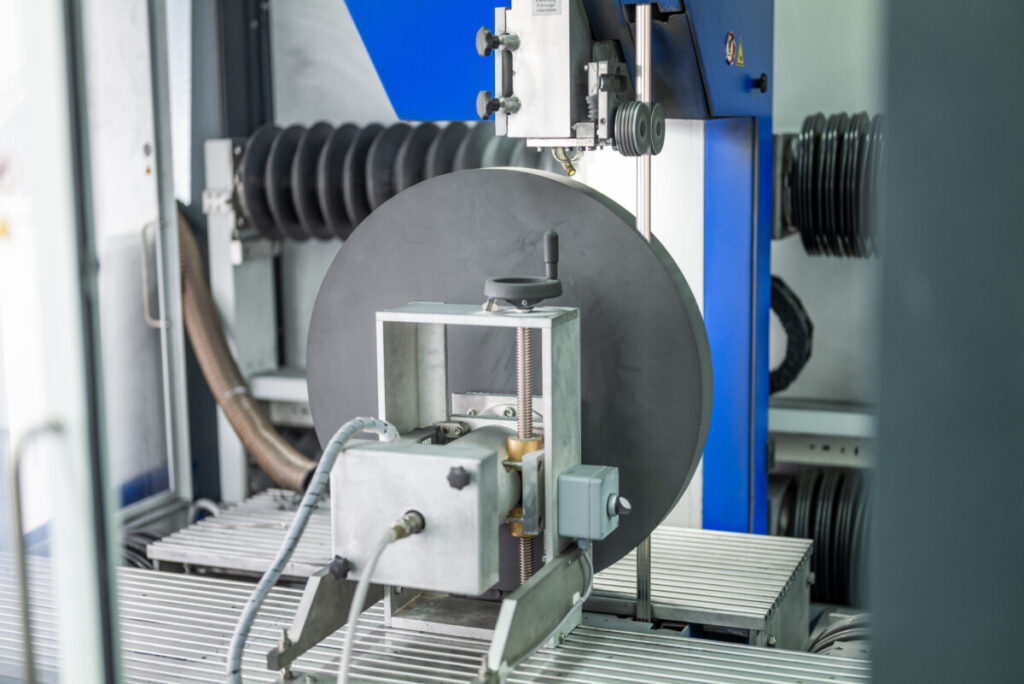

Machines for hybrid bands

Our 270 Series and 400 Series are optimally designed for the use of hybrid bands. Thanks to NC control and variable band speed, both grits on the band can be fully utilized without interrupting the machining process.

Conclusion

Hybrid saw bands combine speed and precision in a single step. For many users, they represent a noticeable increase in productivity and cost-efficiency.

Contact us for more information about hybrid saw bands and the right machine solutions.