Stainless steel is not only corrosion-resistant and durable, but also tough and difficult to machine.

One of the most critical issues during cutting is heat generation: it can lead to distortion, discoloration, and even changes in the material structure.

The Challenge

Conventional cutting methods often generate high temperatures, causing material stresses and surface defects. This is particularly problematic for components with tight tolerances or high-quality surfaces.

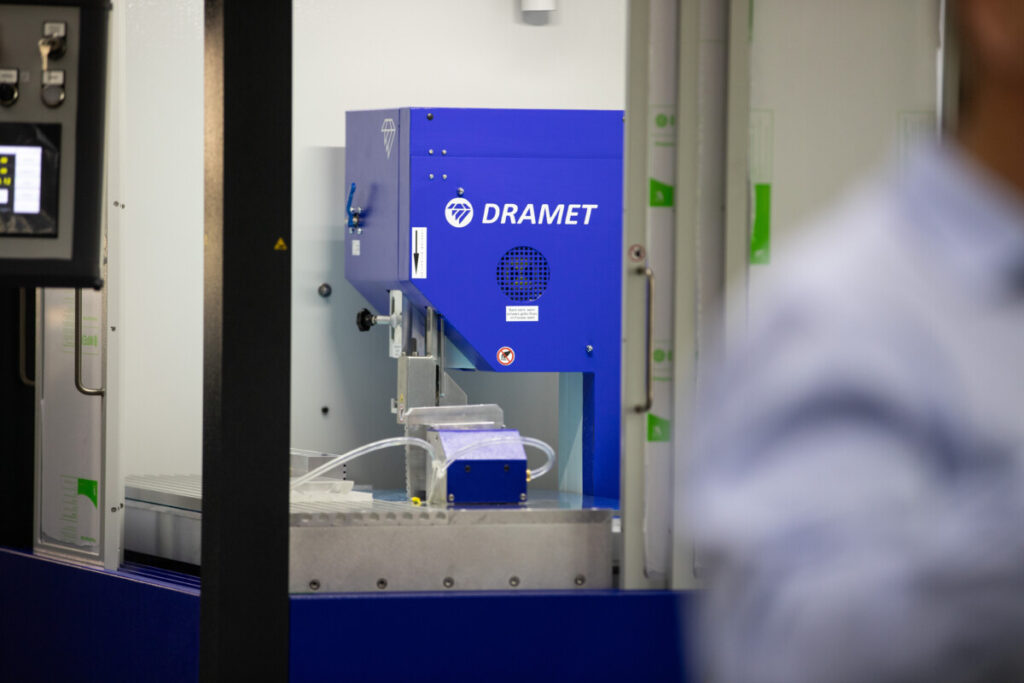

The DRAMET Solution

Our diamond band saws, combined with optional water cooling, cut stainless steel precisely and with virtually no heat development. The cooling simultaneously binds dust and chips, protects the tool, and improves surface quality.

Key Advantages

No thermal distortion, no discoloration

Smooth cut surfaces, often without rework

Longer service life of saw bands

Process reliability even in series production

Suitable Machines

270 Series – flexible and automatable for medium-sized components

400 Series – for large stainless-steel plates or profiles

Conclusion

With DRAMET diamond band saws, you can cut stainless steel precisely, efficiently, and without thermal distortion – ensuring the highest quality in further processing.

Contact us for a non-binding consultation on your stainless-steel machining needs.