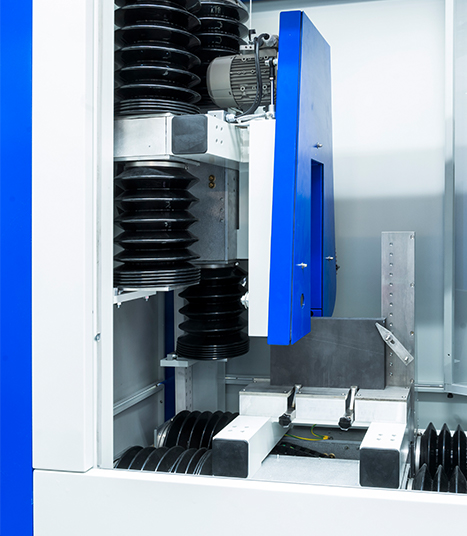

- Diamond Cutting Machine DS150 NC

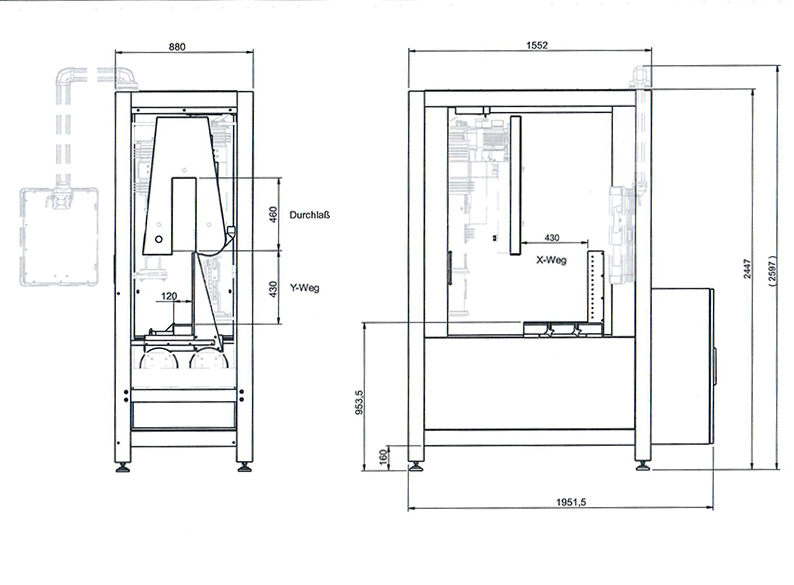

Clearance (HxW) 120 × 460 mm, working area 430 x 430 mm path (X x Y-axis)

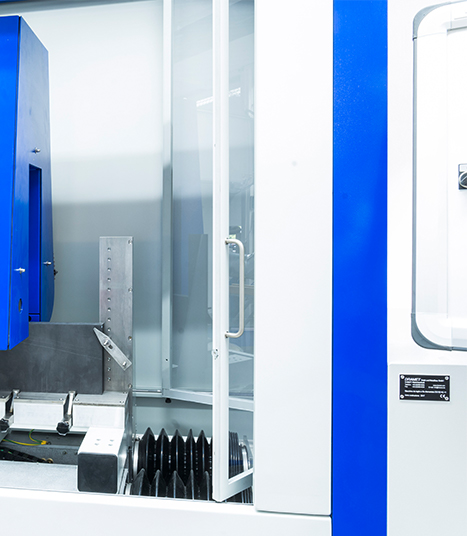

The diamond wire saw DS150 NC is a diamond cut-off machine that is ideal for sawing 2D contours. The wire unit works horizontally so that the sawn part does not fall down but remains in the starting material. The linear guides are encapsulated with round bellows. This guarantees the longevity of the linear guides when sawing abrasive materials. Precise tracing of the pre-programmed contour is made possible by the ball screws used for the feed. The programming of the workpiece contour using external CAD programs is supported by features such as automatic tool radius correction, automatic closing of the contour or the graphic display and process simulation.

The DS150 NC diamond wire saw cuts 2D contours with different materials

Sawing foam in 2D

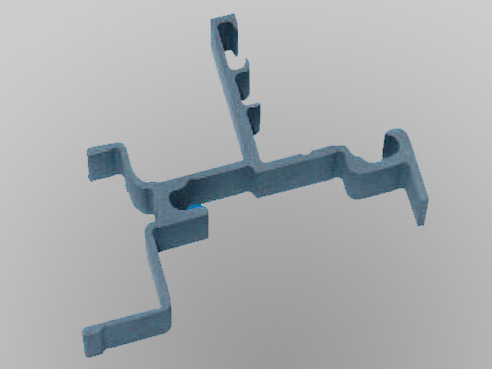

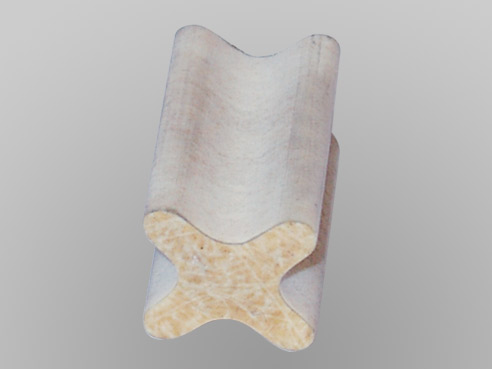

Materials for diamond wire saws, contour cutting from composite material PP with foam

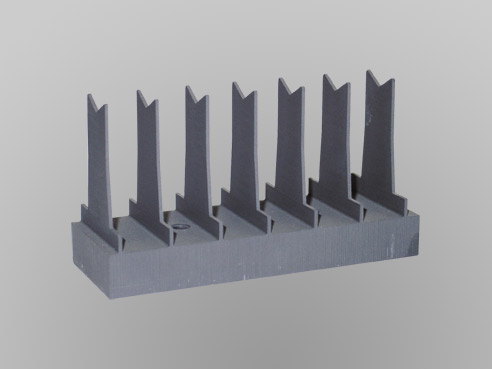

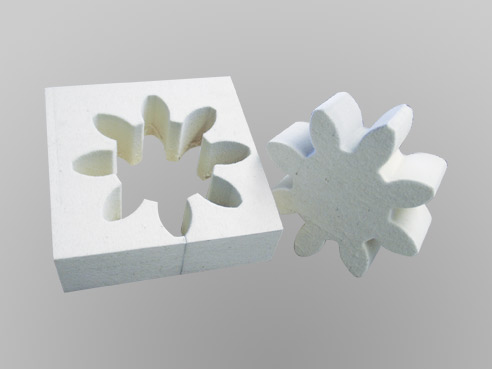

Ceramic green machining with diamond wire saws

Materials for diamond wire saws, cutting 2D contours from felt, sawing

Carbide green machining with diamond wire saws

Materials for diamond wire saws, 2D contours from carbide green compacts cut-off grinding, milling, sawing

GFRP 2D cutting

Materials for diamond wire saws, cutting contours from composite material PP with foam

Felt cutting with diamond wire saws

Materials for diamond wire saws, cutting and sawing 2D contours from felt

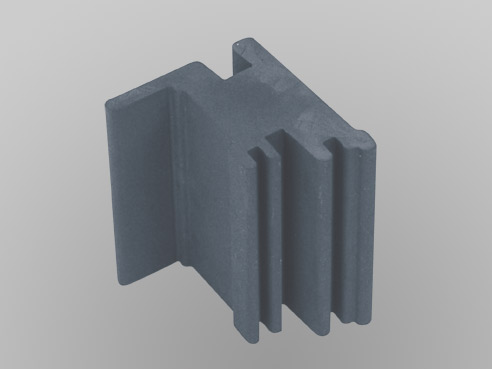

Milling graphite electrodes with diamond wire saws

Materials for diamond wire saws, cut-off grinding, milling, and sawing 2D contours from carbide green compacts

Further technical details on the DS150 NC diamond saw

The workpiece can be moved interpolated in two axes as required for processing. The wire is driven by a frequency converter-controlled three-phase motor. The wire speed is infinitely variable from 100 – 3000 m/min. To insert and tension the wire, the drive motor and the drive roller are moved by a pneumatic cylinder. The wire tension is set via the air pressure adjustable on the pressure reducer.

The programming of the workpiece contour using external CAD programs is supported by features such as automatic tool radius correction, automatic closing of the contour or the graphic display and process simulation. Precise tracing of the contour is made possible by ball screws which, in conjunction with automatic feed deceleration during the machining of radii, achieve optimum results.

The machine is equipped with glass scales for exact positioning of the table.

Extraction takes place directly below the processing area. The grinding dust is pulled downwards by the diamond wire and extracted in a targeted manner.

| Technical Data | Description |

|---|---|

| Length: | 1968 mm |

| Width: | 880 – 890 mm |

| Height: | 2600 mm with control panel |

| Culvert: | 120 mm x 460 mm |

| Work Area (X, Y): | 430 mm, 430 mm |

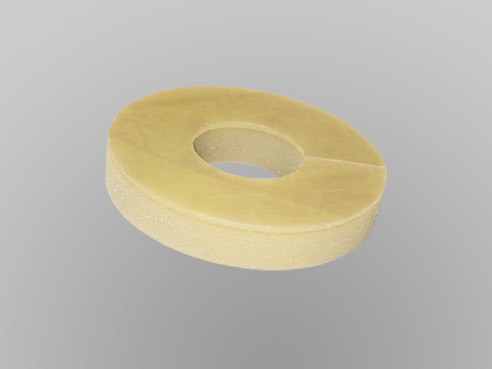

| Roller Diameter: | 150 mm |

| Abrasive Wire: | Ø 0,7 – 1,2 mm Length 2100 mm |

| Wire Speed: | 100 – 3000 m/min |

| Drive: | Three-Phase Motor 750 W |

| Weight: | 600 kg |

Additional options

Cabin safety interlock

Automatic cabin door locking at process start.

Glass scales

Glass scales for precise positioning of the linear axes (X and Y)

Starkstromsteckdose

CEE 400V socket outlet for connection and automatic control of an extraction system

Additional options

Cabin safety interlock

Automatic cabin door locking at process start.

Glass scales

Glass scales for precise positioning of the linear axes (X and Y)

Starkstromsteckdose

CEE 400V socket outlet for connection and automatic control of an extraction system