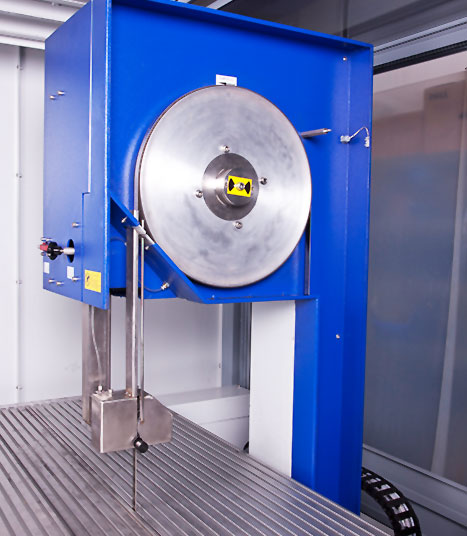

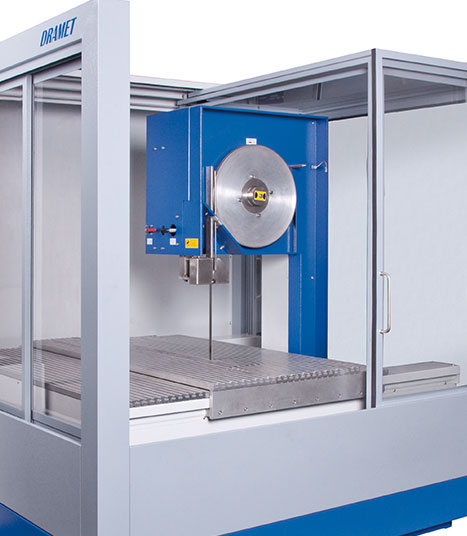

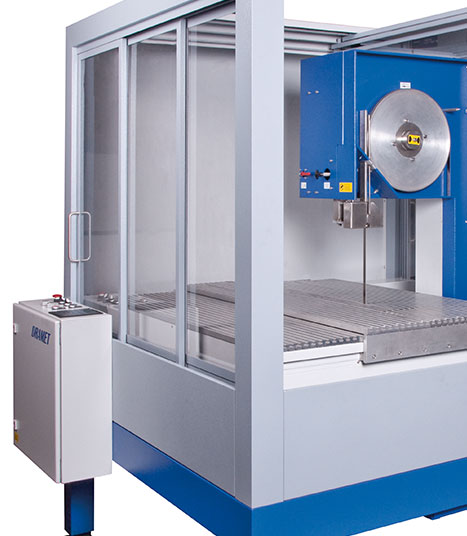

- Diamond Band Saw BS400

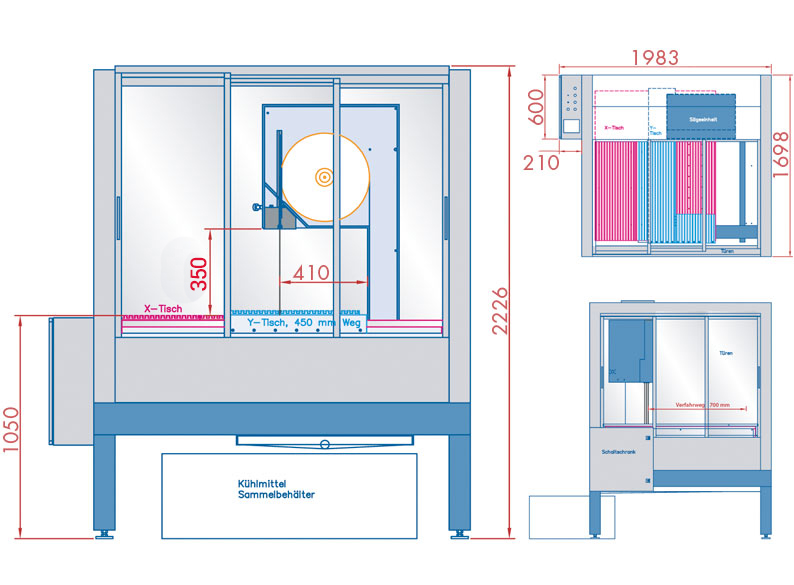

Clearance (HxW) 335× 410 mm, cutting length (X-axis) 700 mm.

The basic version of the BS400 diamond band saw, the BS400 F, is a machine that moves in the X direction.

Equipped as an NC-controlled 2-axis machine, it is available in the BS400 FY version.

The diamond saw is equipped with a cabin and a display as standard. This includes a measuring unit for measuring the feed force. The feed force generated during sawing is displayed on the screen. The feed rate and cutting speed can either be set manually or controlled automatically according to the programmable target force.

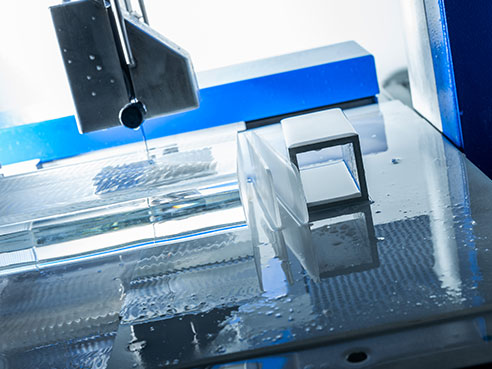

Sawing can be carried out in dry cutting mode or optionally with cooling.

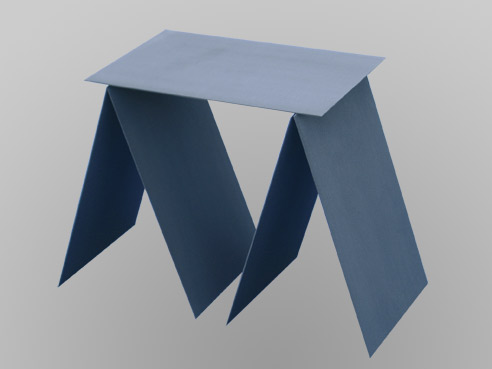

The BS400 FY diamond band saw cuts different materials

Optical glass cutting with diamond band saws

Materials for diamond band saws, glass sawing, cutting, abrasive cutting

Cutting GRP with diamond bandsaws

Materials for diamond band saws, cutting CFRP

Sawing graphite with diamond band saws

Materials for diamond band saws, graphite cut-off grinding

Cutting industrial ceramics with diamond band saws

Materials for diamond band saws, sawing glass, cutting, grinding

Technical ceramics processing with diamond band saws

Technical ceramics processing with diamond band saws

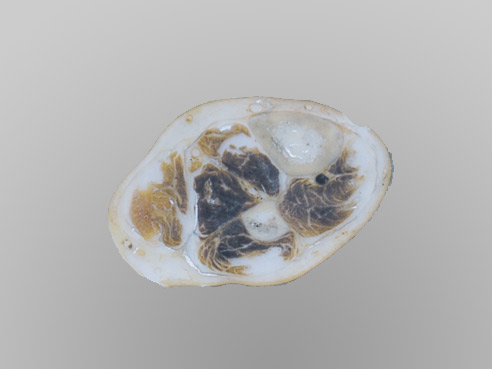

Pathology saw with diamond band

Materials for diamond band saws, sawing, cutting, grinding, and preparing plastinates

Further technical details on the BS400 FY diamond saw

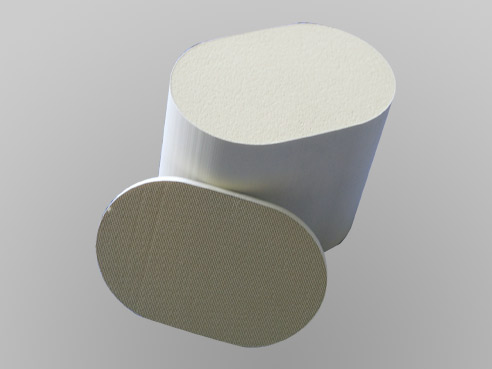

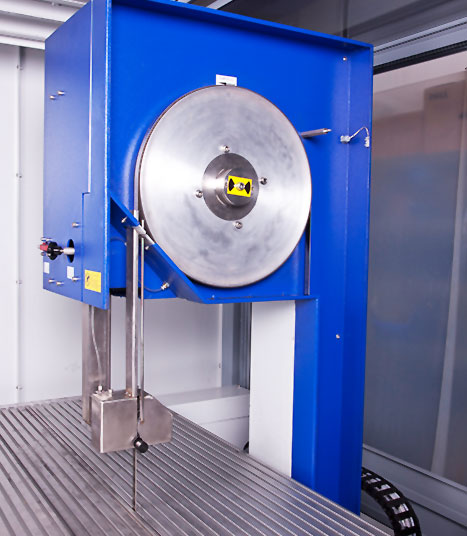

The BS400 F basic version with driven traveling column consists of a belt unit with two deflection rollers D = 420 mm and a clearance (H x W) of 350 x 410 mm. The diamond saw band runs endlessly over two rollers. It is driven and pneumatically tensioned by the upper roller, which is adjustable in height. The band is driven by a frequency converter-controlled 2.2 kW three-phase motor. The belt tension is set via the adjustable air pressure on the pressure reducer. The belt speed can be adjusted from 200 – 3000 m/min using the rotary control.

The belt unit can be moved program-controlled with a ball screw and the servo motor (X-axis). The traverse paths and feed speeds are programmable. The belt unit can be positioned using buttons. Control: Mitsubishi PLC control with touchscreen. The BS400 F becomes the NC-controlled 2-axis machine BS400 FY by equipping it with a Y-table driven by a servo motor.

It can be used for dry cutting or optionally with cooling. For dry cutting, a suction cup is connected to the suction nozzle provided. In the stainless steel machine version, pure water without additives can be used for cooling.

| Technical Data | Description |

|---|---|

| Length: | 1700 mm |

| Width: | 1985 mm |

| Height: | 2230 mm |

| Culvert: | 335 mm x 410 mm |

| Travel Distance (X, Y): | 700 mm |

| Idlers Ø: | 422 mm |

| Guide Rollers Ø: | 70 mm |

| Standard Band: | 0,7 mm x 16 mm, Length 3200 mm |

| Belt Speed: | 200 – 3000 m/min |

| Belt Tension: | 10.000 N |

| Drive: | Three-Phase Motor 2200 W |

| Weight: | 550 kg |

Belt Cleaning

Belt cleaning with high-pressure spray register. High-pressure cleaning of the band saw blade below the processing point ensures that the blade re-enters the cut cleanly.

Coolant system with filter insert

Collecting tray with drain into the coolant tank, coolant pump, coolant supply with stopcock and articulated hose, automatic control of the coolant system. An approx. 0.7 x 0.7 m filter fleece can be inserted and replaced if necessary.

Additional options

Higher clearance for workpiece heights up to 600 mm

Coolant system with filter insert

Collecting tray with drain into the coolant tank, coolant pump, coolant supply with stopcock, automatic control of the coolant system. A filter fleece measuring approx. 0.7 x 0.7 m can be inserted and replaced if necessary.

Coolant system with fresh water supply

When cutting silicon, as silicon can only be filtered insufficiently . This leads to heavy contamination of the cooling water. Fresh water consumption approx. 2-5 l/min.

Coolant system with deep-bed belt filter

Collecting tray with outlet into the deep-bed belt filter, filter fleece roll on transport roller, deep-bed belt filter with collection container, coolant pump, coolant supply with stopcock, automatic control of the coolant system.

High-pressure belt cleaning

High-pressure coolant pump, supply line, nozzle for belt cleaning

NIRO version. Stainless steel version

Support and plates of the machine and the coolant system made of aluminum or stainless steel, shafts and bearings made of stainless steel. With this version, pure water can be used without the addition

Line laser

to display the cutting line

Spray booth interlock

The cabin is automatically locked during the cutting process.

Power socket

For connection and automatic control of a suction unit

Additional options

Higher clearance for workpiece heights up to 600 mm

Coolant system with filter insert

Collecting tray with drain into the coolant tank, coolant pump, coolant supply with stopcock, automatic control of the coolant system. A filter fleece measuring approx. 0.7 x 0.7 m can be inserted and replaced if necessary.

Coolant system with fresh water supply

When cutting silicon, as silicon can only be filtered insufficiently . This leads to heavy contamination of the cooling water. Fresh water consumption approx. 2-5 l/min.

Coolant system with deep-bed belt filter

Collecting tray with outlet into the deep-bed belt filter, filter fleece roll on transport roller, deep-bed belt filter with collection container, coolant pump, coolant supply with stopcock, automatic control of the coolant system.

High-pressure belt cleaning

High-pressure coolant pump, supply line, nozzle for belt cleaning .

NIRO version. Stainless steel version

Support and plates of the machine and the coolant system made of aluminum or stainless steel, shafts and bearings made of stainless steel. With this version, pure water can be used without the addition of .

Line laser

to display the cutting line

Spray booth interlock

The cabin is automatically locked during the cutting process.

Power socket

For connection and automatic control of a suction unit