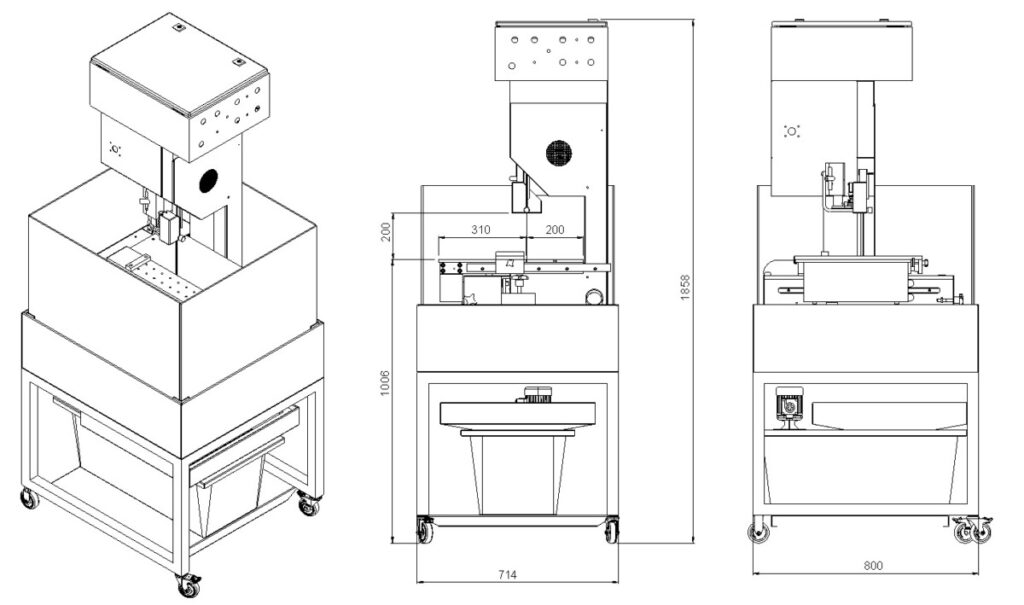

- Diamond Band Saw BS200S

Passage (HxW) 200×200 mm, cutting length (X-axis) 200 mm. Footprint 800 x 714 mm, height 1858 mm.

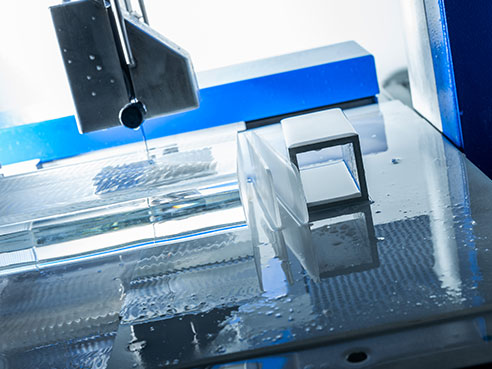

The diamond band saw BS200 S has a sliding table that is pushed manually during the sawing process. The sliding table can also move independently under its own weight during the sawing process.

The materials to be cut can be cut to different thicknesses. The slice thickness is easily set using the manually adjustable stop.

This diamond saw cuts in a dry cut. Optionally, your materials can be cut with cooling, which improves the surface quality and tolerance under certain circumstances, as well as enabling higher feed rates and therefore shorter running times.

The BS200S diamond band saw cuts different materials

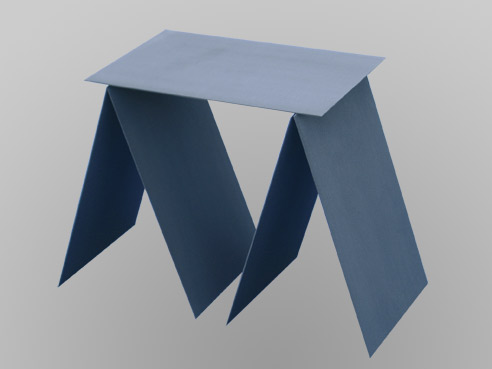

Optical glass cutting with diamond band saws

Materials for diamond band saws, glass sawing, cutting, abrasive cutting

GRP sawing with diamond band saws

Materials for diamond band saws, cutting CFRP

Sawing graphite with diamond band saws

Materials for diamond band saws, graphite cut-off grinding

Cutting industrial ceramics with diamond band saws

Materials for diamond band saws, sawing glass, cutting, grinding

Technical ceramics processing with diamond band saws

Technical ceramics processing with diamond band saws

Pathology saw with diamond band

Materials for diamond band saws, sawing, cutting, grinding, and preparing plastinates

Further technical details on the BS200 S diamond saw

The diamond band saw BS200 S consists of a band unit with two deflection rollers D = 230 mm and a passage (H x W) of 200 x 200 mm. The diamond saw band runs endlessly over two rollers. It is driven and pneumatically tensioned by the upper roller, which is adjustable in height. The band is driven by a frequency converter-controlled 750 watt three-phase motor. The belt tension is set via the adjustable air pressure on the pressure reducer. The belt speed is infinitely variable from 200 – 2200 m/min.

The linear guide of the sliding table can be tilted using an adjusting screw. Due to its own weight, the table moves with constant feed force without manual operation.

It can be used for dry cutting or optionally with cooling. For dry cutting, a suction cup is connected to the suction socket provided. In the stainless steel machine version, pure water without additives can be used for cooling…

| Technical Data | Description |

|---|---|

| Length: | 800 mm |

| Width: | 714 mm |

| Height: | 1858 mm |

| Culvert: | 200 mm x 200 mm |

| Travel Distance (X, Y): | 220 mm, 210 mm |

| Idlers Ø: | 230 mm |

| Guide Rollers Ø: | 47 mm |

| Standard Band: | 0,7 mm x 8 mm, Length 1870 mm |

| Belt Speed: | 200 – 2200 m/min |

| Belt Tension: | 2.000 N |

| Drive: | Three-Phase Motor 750 W |

| Weight: | 110 kg |

Additional options

Y stop

Stop resting on the X-table for the Y-direction (with clamping), manually adjustable. To cut off slices, the workpiece can be clamped to it and moved in parallel

Coolant system with filter insert

Collecting tray, coolant filter, coolant pump, coolant supply with stopcock, automatic control of the coolant pump. A filter fleece measuring approx. 0.7 x 0.7 m can be inserted and replaced as required . The machine is equipped with polycarbonate panes as splash water protection. Including Machine base frame with castors

NIRO version, stainless steel version

Support and plates of the machine and the coolant system made of aluminum, shafts and bearings made of stainless steel.

Base frame with castors

Machine base frame with castors for installation of the BS200S table version if the machine is equipped without a coolant system.

Line laser

Line laser for displaying the cutting line

Additional options

Y stop

Stop resting on the X-table for the Y-direction (with clamping), manually adjustable. To cut off slices, the workpiece can be clamped to it and moved in parallel

Coolant system with filter insert

Collecting tray, coolant filter, coolant pump, coolant supply with stopcock, automatic control of the coolant pump. A filter fleece measuring approx. 0.7 x 0.7 m can be inserted and replaced as required . The machine is equipped with polycarbonate panes as splash water protection. Including Machine base frame with castors

NIRO version, stainless steel version

Support and plates of the machine and the coolant system made of aluminum, shafts and bearings made of stainless steel.

Base frame with castors

Machine base frame with castors for installation of the BS200S table version if the machine is equipped without a coolant system.

Line laser

Line laser for displaying the cutting line