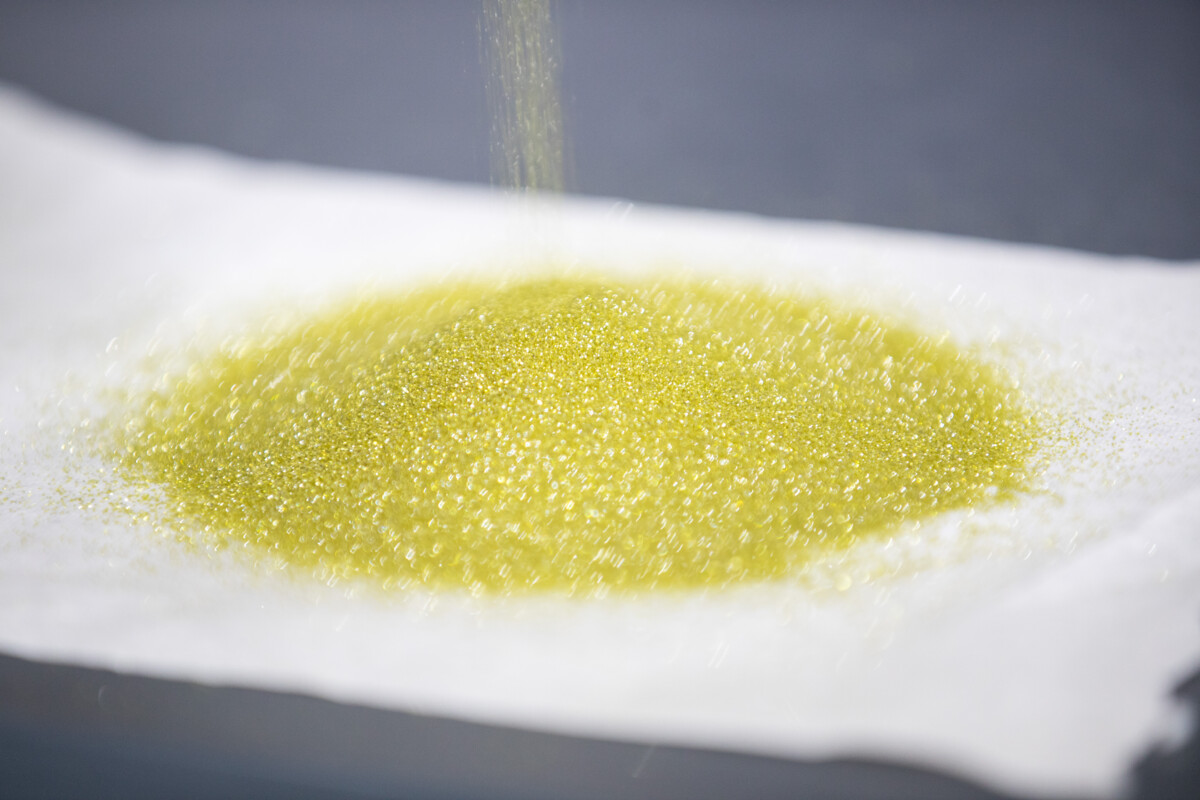

Diamond and Cubic Boron Nitride (CBN) are among the hardest known cutting materials – making them ideal for sawing and cut-off grinding of demanding materials. However, the choice of the right cutting medium depends heavily on the material and the specific application.

Diamond – The All-Rounder for Non-Metals

Diamond is the hardest known material and offers outstanding cutting performance for brittle, abrasive materials such as graphite, ceramics, glass, CFRP/GFRP, or semiconductor materials.

Advantages:

• Excellent surface quality

• Very narrow kerfs (0.16–0.35 mm)

• Long tool life with abrasive materials

Limitation: Diamond reacts with iron at high temperatures – therefore not suitable for cutting steels.

CBN – The Specialist for Metals

CBN (Cubic Boron Nitride) is the second hardest known material after diamond but is chemically stable in contact with ferrous materials. It is ideal for high-alloy steels as well as titanium- and nickel-based alloys.

Advantages:

• Chemically stable against iron

• High thermal resistance

• Excellent tool life with tough metals

Limitation: Less suitable for brittle, non-metallic materials.

Conclusion

Diamond is the first choice for non-metallic, abrasive materials – while CBN is unbeatable for metalworking.

DRAMET offers both cutting materials in various grain sizes and band thicknesses, perfectly matched to your application.

Contact us for expert advice on selecting the optimal cutting medium.