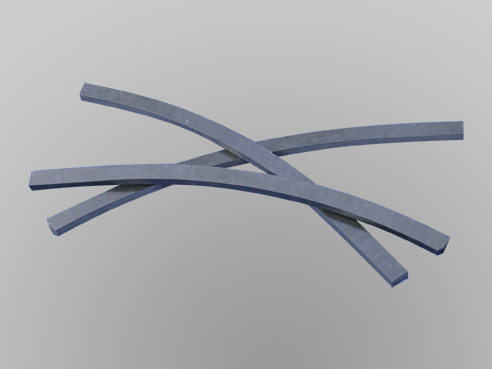

Fiber-reinforced plastics such as CFRP (carbon fiber-reinforced plastic) and GFRP (glass fiber-reinforced plastic) are extremely lightweight, strong, and versatile. They are used in aerospace, automotive, medical technology, and motorsports. However, machining them is demanding, as the combination of hard fibers and a soft matrix can lead to delamination, fraying, and severe tool wear.

Challenges in CFRP/GFRP

Fiber breakouts and delamination at the cut edges

Heavy abrasion and high stress on tools

Generation of health-damaging fine dust

Different material properties within one component

The DRAMET Solution

Our diamond-coated saw bands cut CFRP and GFRP precisely and without chipping. The combination of minimal cutting pressure, narrow kerf, and high band speed ensures clean cut surfaces, while integrated extraction and water cooling reliably bind and remove the dust generated.

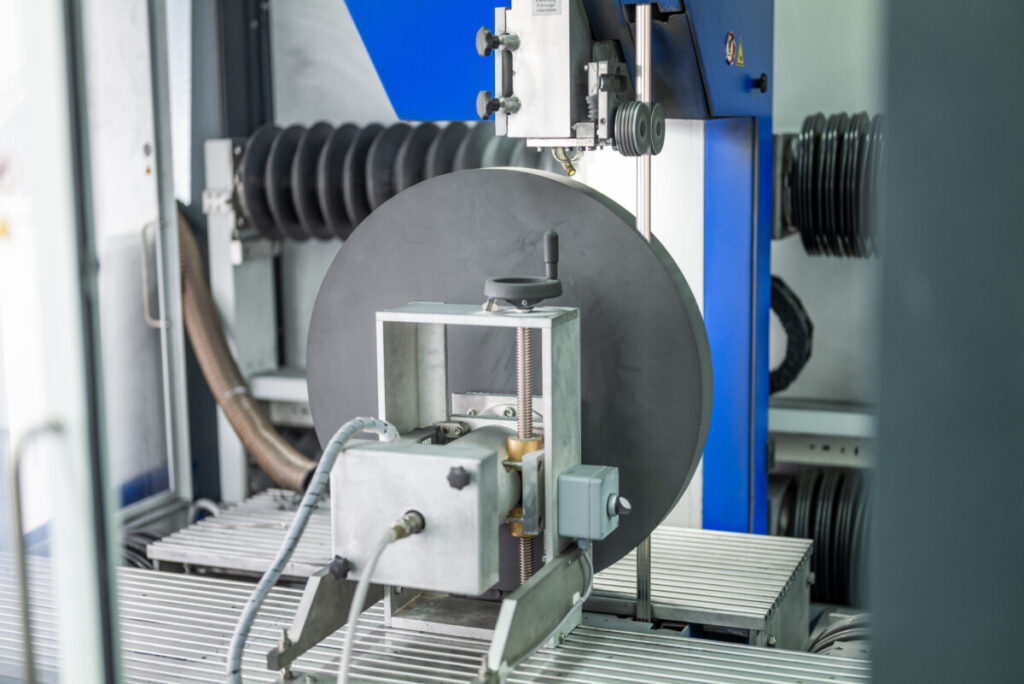

Suitable Machines

200 Series – compact, ideal for smaller CFRP/GFRP components in prototype production

270 Series – flexible, automatable, and suitable for medium to large workpieces

400 Series – for large-format plates or profiles, also in series production

Conclusion

With DRAMET diamond band saws, you can machine CFRP and GFRP components precisely, cleanly, and with minimal material waste – without delamination, with maximum cutting quality, and with optimized tool life.

Contact us for a non-binding consultation on your application.