Optical glass is a high-performance material used across many key industries – from medical technology and aerospace to high-end camera systems. The demands on surface quality and dimensional accuracy are especially high here – even the smallest defects or stresses can impair functionality.

Challenges in Glass Processing

Optical glass is hard, brittle, and sensitive to both thermal and mechanical stresses. Conventional cutting methods often result in edge chipping, microcracks, or stresses within the material. This means additional grinding or polishing – and therefore higher costs.

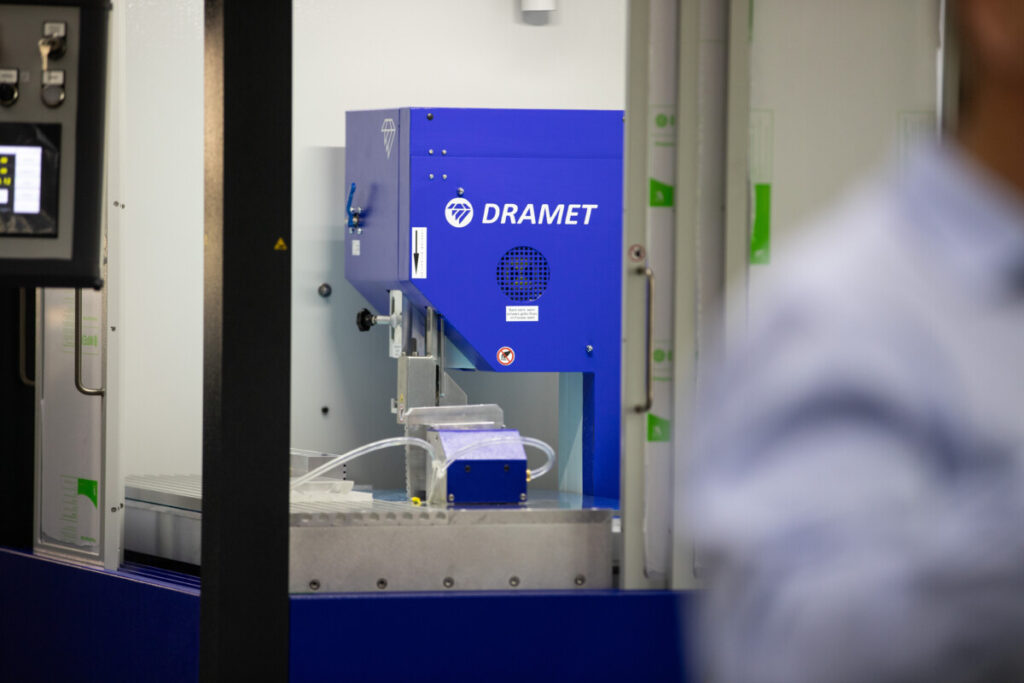

The DRAMET Solution: Diamond Band Saws with Grinding-Quality Results

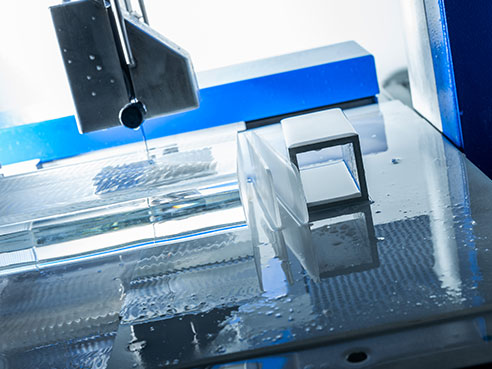

Our diamond band saws are engineered to cut even the most delicate glass types precisely and gently. With their combination of an extremely narrow kerf (0.45 – 0.85 mm), minimal cutting pressure, and fine-grit diamond-coated saw bands, they produce smooth cut surfaces that are often ready for use without further finishing.

Suitable Machine Models

200 Series – compact and precise, ideal for smaller glass components and laboratory applications

270 Series – flexible, automatable, and perfect for medium-sized workpieces

400 Series – for large glass plates or thick-walled components, with high band speed for efficient cuts

Conclusion

With DRAMET diamond band saws, even the most sensitive glass types can be processed gently, precisely, and economically – with minimal need for rework.

Contact us for a non-binding consultation on your glass processing needs.