In modern manufacturing, it is no longer sufficient to achieve good results—they must also be traceable, reproducible, and fully documented. Especially when machining sensitive and high-value materials such as graphite, ceramics, optical glass, or semiconductor materials, quality is not a matter of chance but the result of controlled processes. This is where data plays a central role.

Why transparency in the cutting process is crucial

Many quality issues develop gradually: slight variations in material batches, minimal tool wear, or small deviations in cutting parameters. Without measurable data, these changes often go unnoticed until scrap occurs or rework becomes necessary. Transparent processes make such deviations visible at an early stage and allow targeted corrective action.

Cutting force as a key parameter

One of the most meaningful indicators of cutting quality is cutting force. It directly reflects the load applied to the workpiece during the cutting process. Increasing forces can indicate dull saw bands, incorrect feed rates, or clamping issues—long before visible defects appear.

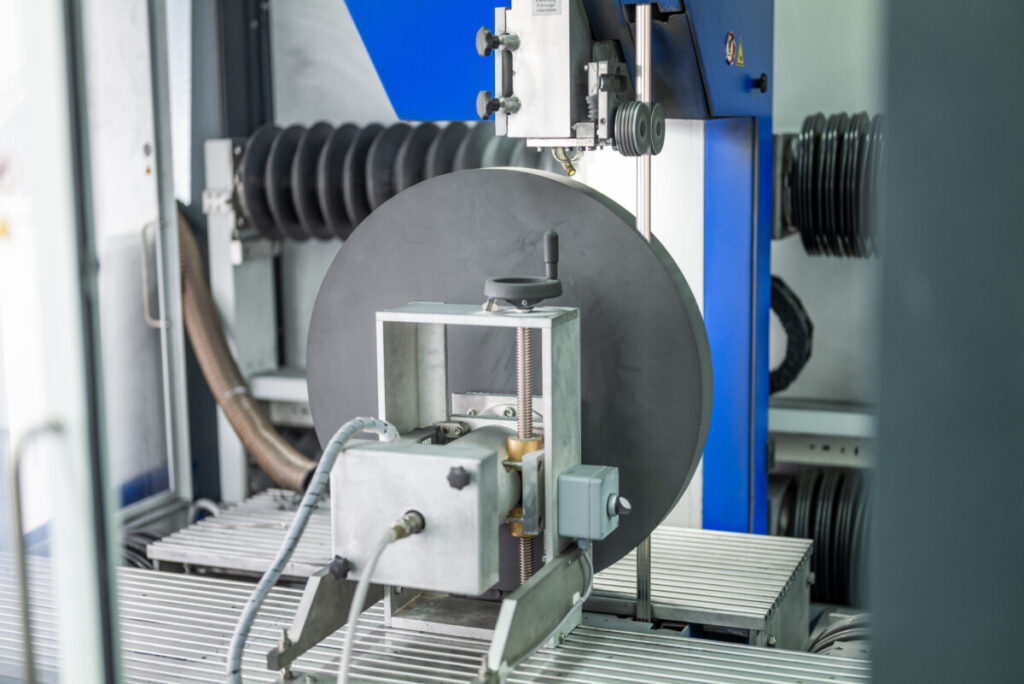

For this reason, DRAMET optionally integrates cutting force measurement systems that continuously monitor the process and ensure reproducibility.

Data creates security—for operators and processes

By recording relevant process data, operators receive clear feedback on the condition of the machine, the tool, and the workpiece. This not only increases process reliability but also reduces dependence on subjective experience. Settings can be documented, compared, and optimized in a targeted manner—an essential advantage when working with varying materials or in series production.

Quality assurance and documentation

In many industries—such as medical technology, semiconductor manufacturing, or research—process documentation is mandatory. Data-driven cutting processes allow parameters to be clearly traced and used for audits or quality verification. This builds trust with customers and partners and simplifies internal approval procedures.

From single applications to series approval

Data-based transparency is not only relevant for series production. Even in laboratory environments or prototype manufacturing, it enables stable results and facilitates the transition to series production. Those who make processes measurable at an early stage avoid later adjustments and create a solid foundation for scalability. DRAMET supports this path with machine concepts that intelligently combine precision and data acquisition.

Conclusion

Quality is created where processes are understood and controlled. With data-based process monitoring, cutting force measurement, and reproducible control systems, DRAMET brings transparency to the cutting process. This reduces scrap, increases safety, and makes quality measurable—cut by cut.

Contact us for a non-binding consultation on how data-driven cutting processes can make your production more transparent and efficient.