In many manufacturing processes, precision begins with trial and error. Parameters are adjusted, initial cuts are evaluated, settings are corrected—until the result is acceptable. What may still be tolerable in prototyping, however, quickly becomes a cost factor in series production. Scrap, rework, and process uncertainty are often the result. This is exactly where process stability comes into play.

Why a single perfect cut is not enough

A single precise cut is not proof of quality. A process only becomes stable when results can be reproduced reliably over many cycles. Especially with sensitive materials such as graphite, technical ceramics, optical glass, or composite materials, even the smallest fluctuations in cutting pressure, feed rate, or band guidance can lead to dimensional deviations, chipping, or surface defects.

Reproducibility as a quality factor

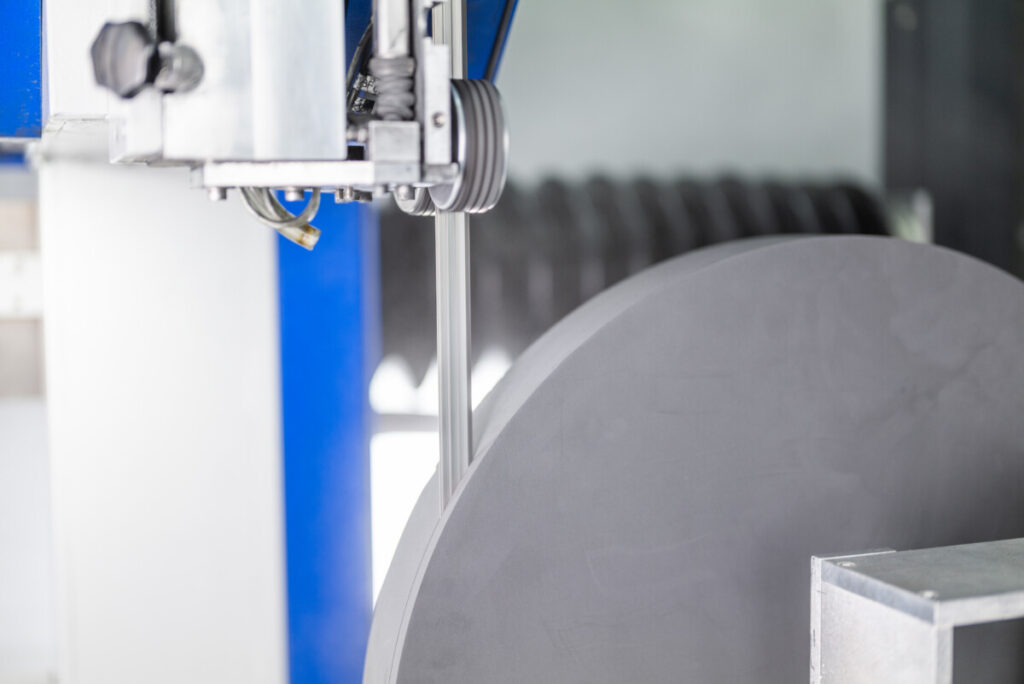

Process-stable cutting technology ensures that every operation is performed identically—regardless of operator, shift, or batch size. DRAMET diamond band saws are designed to keep cutting parameters constant and detect fluctuations at an early stage. This reduces scrap, lowers post-processing costs, and increases planning reliability.

Technology instead of trial & error

DRAMET relies on technical solutions that make process stability measurable.

NC controls enable precisely repeatable cutting motions. Integrated cutting force measurement monitors the process in real time and detects deviations during cutting. Precise band guidance, rigid machine structures, and matched diamond or CBN saw bands ensure consistently high cutting quality—even in series production.

Less scrap, greater economic efficiency

A stable process has a direct impact on cost structures. Less scrap means lower material loss, particularly with high-value materials. At the same time, the need for rework decreases, and tool life can be planned more reliably. Customers report significantly reduced scrap rates and a noticeable relief in production—both technically and economically.

From individual applications to series production

Process stability is not only relevant for large-scale production. In research, development, and small-batch manufacturing, it also builds confidence in results and facilitates scaling. Anyone who works with reproducible cuts already in the laboratory lays the foundation for safe series approval. DRAMET supports this journey—from the first application to automated production.

Conclusion

Precision is not achieved through trial and error, but through stable processes. With reproducible cutting technology from DRAMET, companies reduce scrap, improve quality, and gain confidence in their manufacturing operations. A controllable process is the key to sustainable success.