The industrial manufacturing sector faces increasing pressure in 2025: energy prices remain high, raw materials are becoming more expensive, and skilled labor is in short supply. At the same time, expectations around quality, sustainability, and speed are rising. Companies that want to remain competitive must make their processes more efficient—without compromising precision or reliability.

Efficiency begins at the cut

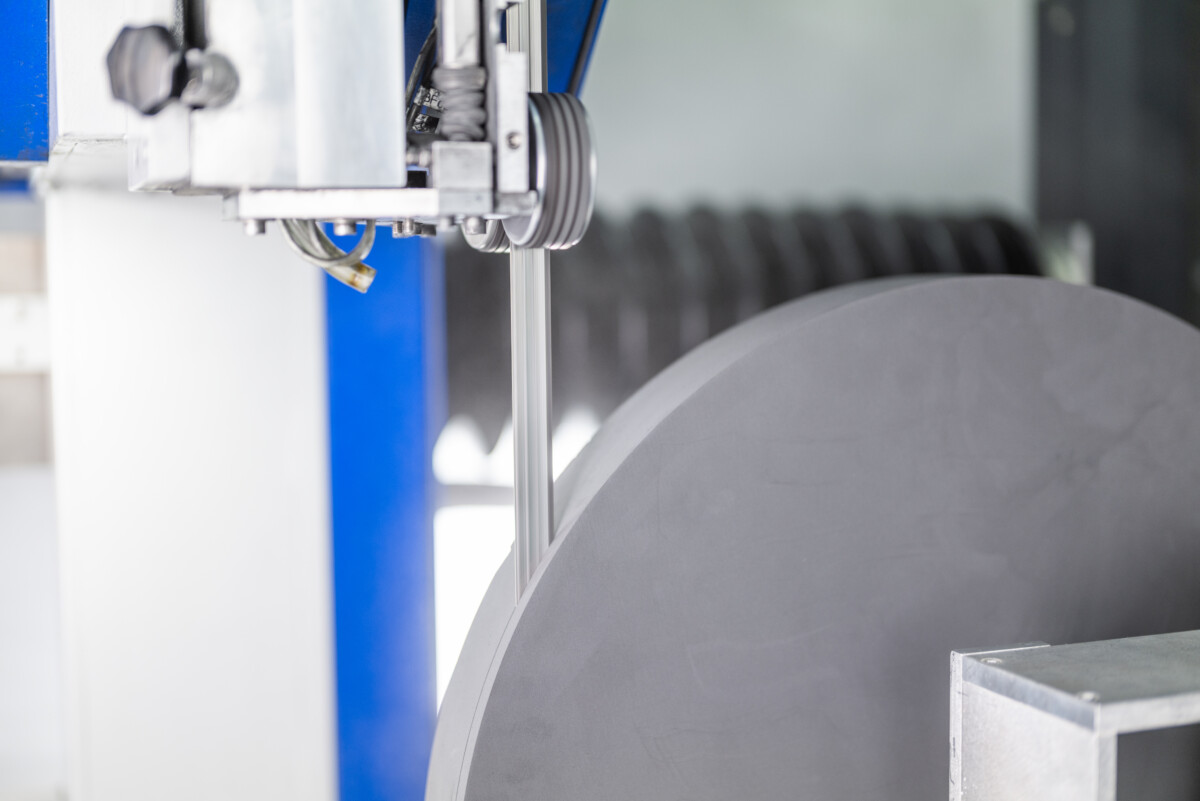

Every machining step consumes energy, material, and time. Especially when cutting and grinding demanding materials such as graphite, ceramics, glass, or metals, the technology used determines the overall efficiency of production.

DRAMET diamond band saws are designed to operate with minimal cutting pressure (0.5–4 N) and extremely narrow kerfs of only 0.45–0.85 mm. This means less material loss, lower energy consumption, and a significant reduction in post-processing time.

Material preservation = cost savings

With high-value materials such as optical glass, graphite, or technical ceramics, every millimeter of kerf width translates into noticeable costs. Thanks to precise band guidance and diamond-coated saw bands, DRAMET machines produce surfaces that often require no additional grinding or polishing. This saves time, reduces tool wear, and lowers energy usage.

Sustainable manufacturing through long-lasting machines

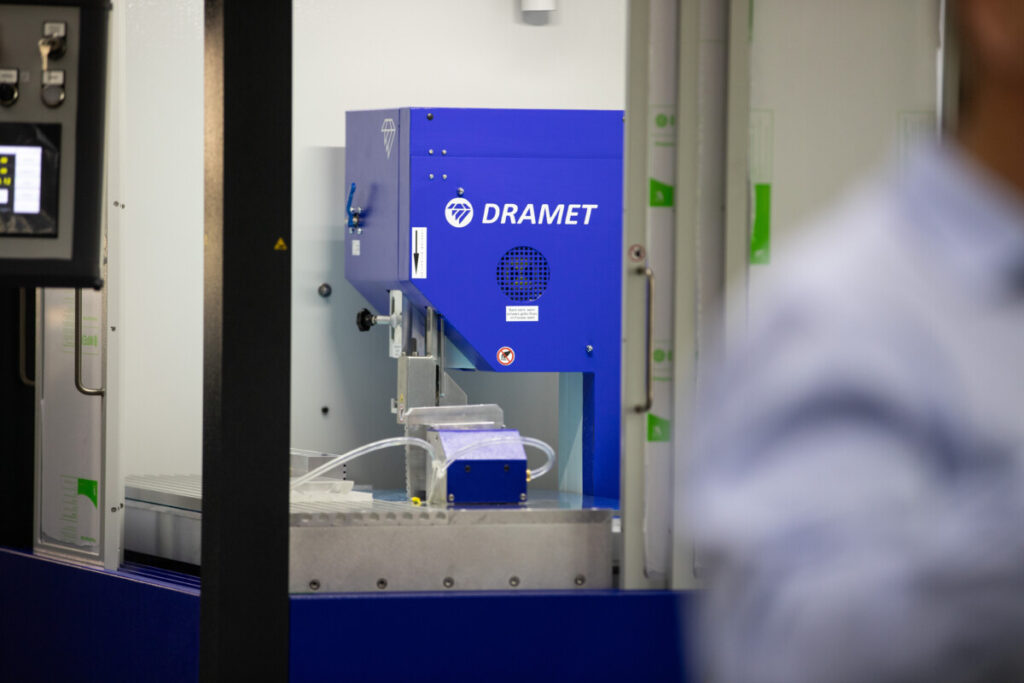

Another major contribution to economic efficiency lies in machine longevity. DRAMET relies on robust designs, low-maintenance components, and high-quality materials—“Made in Germany.” The machines are built to last for decades and can be upgraded with modular options such as NC control, extraction systems, or water cooling. This reduces lifecycle CO₂ emissions and saves long-term operating costs.

Examples from practice

Customers from the electronics, medical technology, and materials industries report process time reductions of up to 30% and significantly lower material consumption. The combination of narrow kerfs, reproducible precision, and automated process control ensures that every cut counts—and every kilowatt-hour pays off.

Conclusion

Energy efficiency and cost reduction do not begin with the electricity bill—they begin in the machining process. With DRAMET diamond band saws, companies reduce material and energy consumption, extend tool life, and increase productivity—an investment that pays off quickly in times of rising costs.

Contact us for a non-binding consultation on how DRAMET can help make your production more efficient and economical.