In modern manufacturing, it’s no longer just about individual precise cuts – what truly matters are repeatable results, delivered in identical quality over thousands of cycles.

In industries such as semiconductor technology, medical engineering, or aerospace, process reliability is the key to success.

Why automation matters

Consistent quality: NC-controlled machines execute cutting parameters with perfect repeatability.

Time efficiency: Automated feed rates and programmed cutting sequences reduce setup and machining time.

Error reduction: Fewer operator interventions mean less variability in the final result.

Data-driven process control: Integrated sensors monitor cutting forces and machine condition.

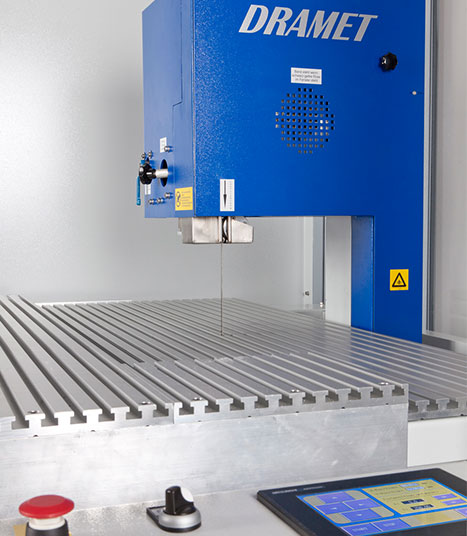

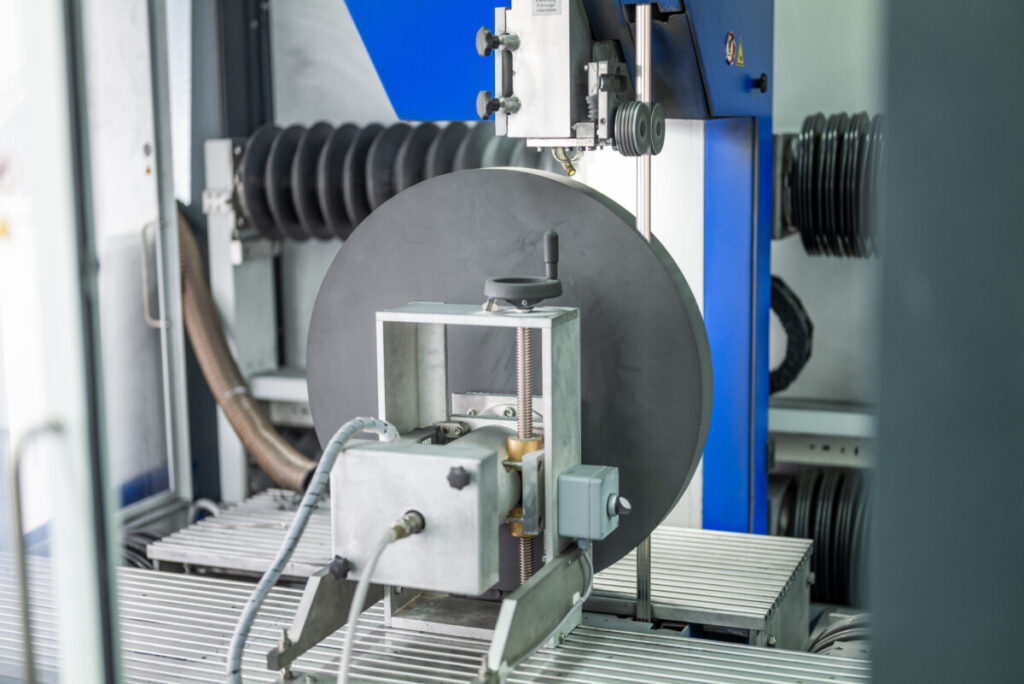

The DRAMET solution

Our 270 and 400 series machines are equipped with NC control and optional automation packages. This enables fully automated machining – from material loading to the precise replication of the final cut.

Your benefits

Increased output per shift

Reduced scrap rates

Scalability from small to large batch production

Reduced workload for operating staff

Conclusion

In precision machining, automation is not a luxury – it is a competitive advantage. DRAMET delivers machines that combine consistent quality with maximum productivity.

Contact us for a non-binding consultation on your automation options.