The semiconductor industry works with materials that are both extremely valuable and highly sensitive. Silicon, quartz, sapphire, or gallium arsenide are used in wafers, substrates, and specialized components. Their processing requires the utmost precision to avoid compromising the functionality of the parts.

Challenges in Semiconductor Materials

Sensitivity to mechanical stresses

Risk of microcracks or thermally induced stresses

High quality requirements for surfaces

High material costs – every millimeter counts

The DRAMET Solution

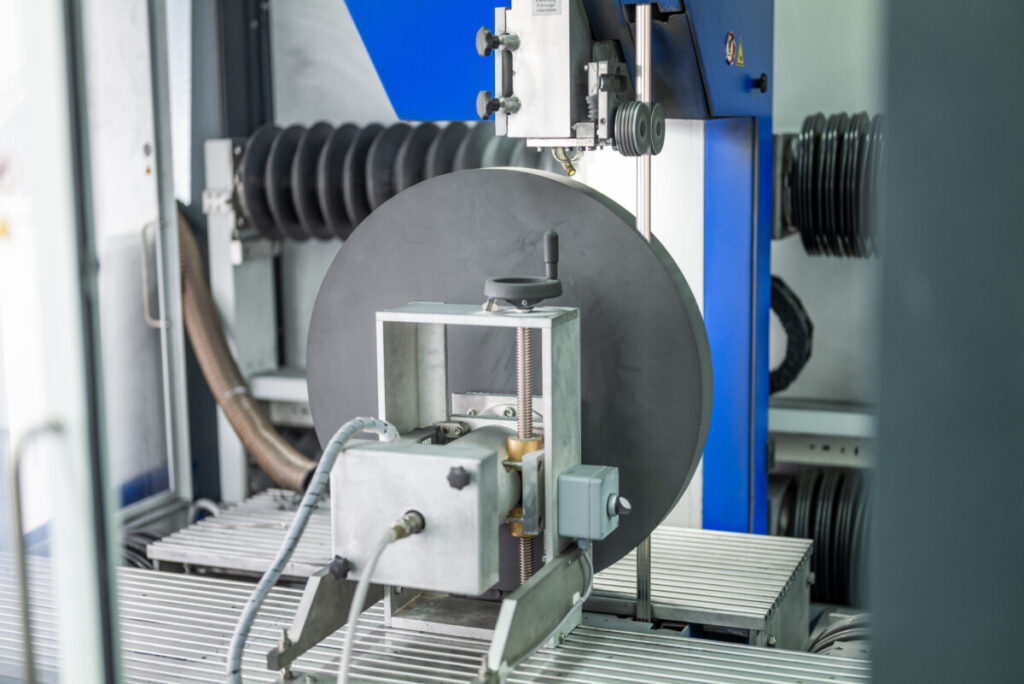

Our fine-grit, diamond-coated saw bands deliver smooth, chip-free edges at minimal cutting pressure. Kerfs of only 0.16–0.35 mm significantly reduce material loss. NC control and process monitoring ensure reproducible results – ideal for series production.

Suitable Machines

200 Series – for small, delicate workpieces in laboratories and prototype production

270 Series – flexible and automatable for medium-scale series

400 Series – powerful for larger wafer carriers or quartz plates

Conclusion

With DRAMET diamond band saws, you achieve maximum precision, minimal material loss, and reproducible quality in semiconductor processing.

Contact us for a non-binding consultation on your application.