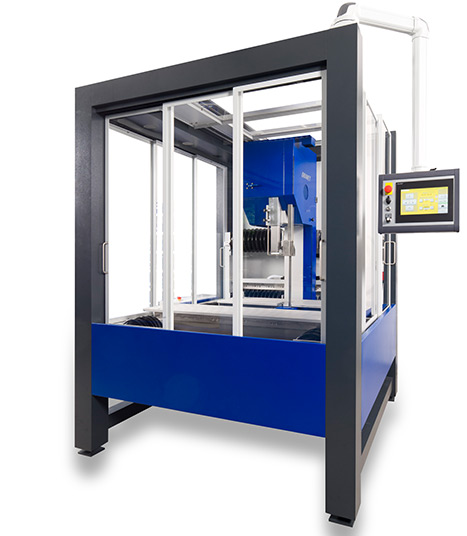

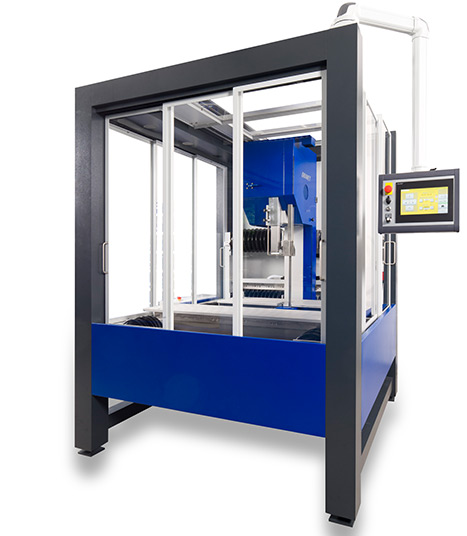

- Diamantbandsäge BS422 A – H600 FY

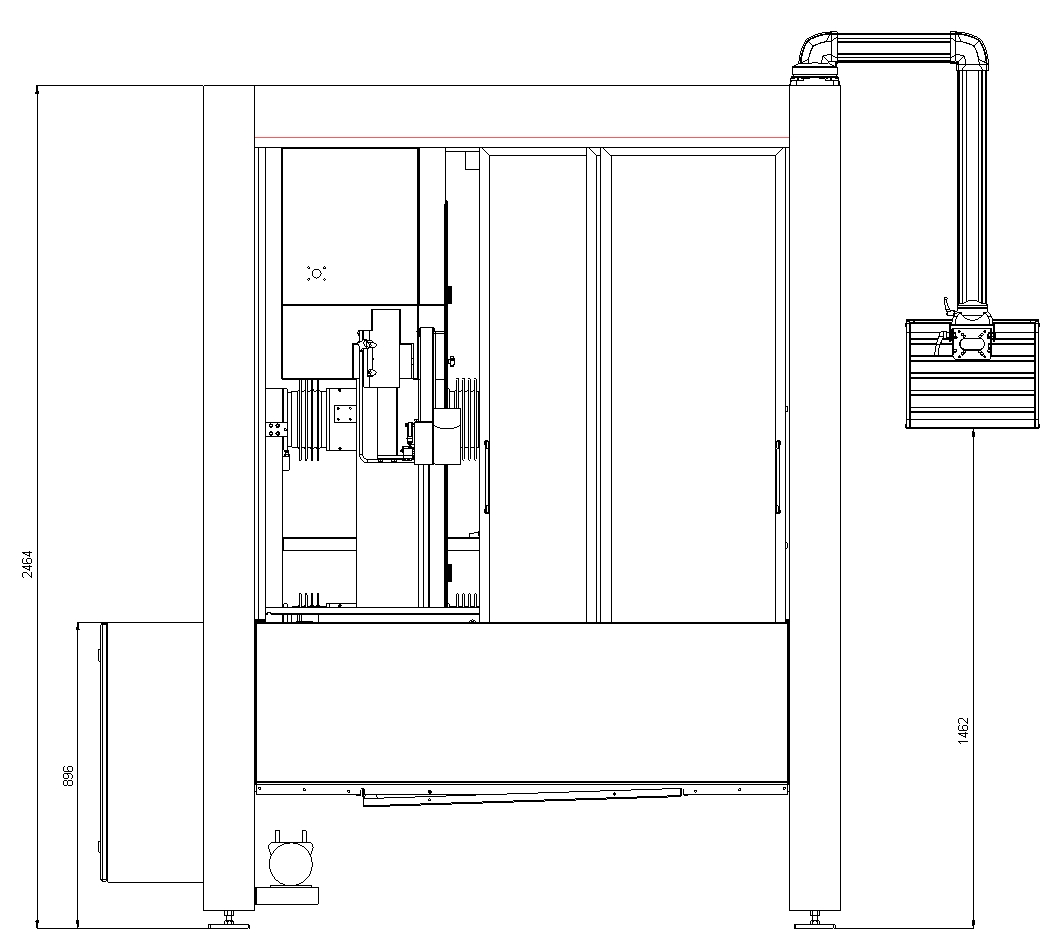

Durchlass (HxB) 610 × 410 mm, Schnittlänge (X-Achse) 620 mm.

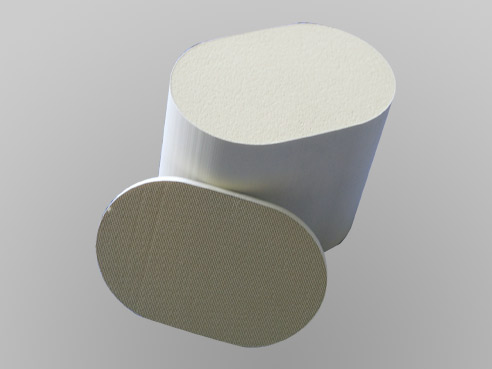

Die Diamantbandsäge BS422 A – H600 FY mit angetriebenem Fahrständer hat eine Bandeinheit und zwei Umlenkrollen. Das Diamantsägeband läuft endlos über zwei Rollen und die obere Rolle ist in der Höhe verstellbar.

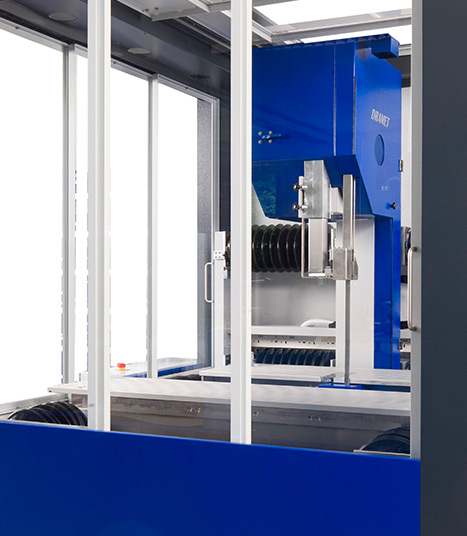

Die Maschinenkabine ist durch Plexiglasscheiben geschützt. Zur Sicherheit schaltet sich die Maschine bei offener Tür automatisch ab. Verschiedene Möglichkeiten beim Schnitt machen die Maschine zu einer Hochleistungseinheit. Es kann mit Wasser und Kühlung gesägt werden.

Die Diamantbandsäge BS422 A – H600 FY schneidet unterschiedliche Materialien

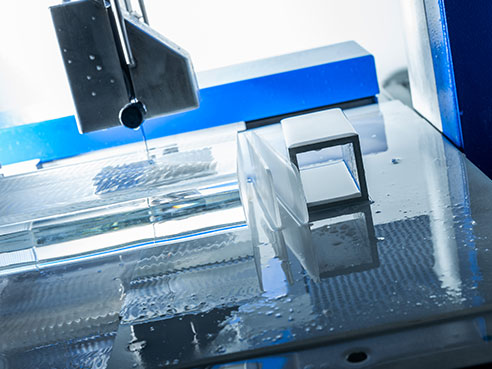

Optisches Glas Zuschnitt mit Diamantbandsägen

Materialien für Diamantbandsägen, Glas sägen, schneiden, trennschleifen

GFK sägen mit Diamantbandsägen

Materialien für Diamantbandsägen, CFK trennen

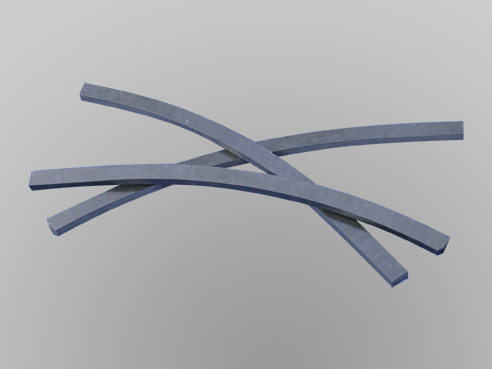

Graphit sägen mit Diamantbandsägen

Materialien für Diamantbandsägen, Graphit trennschleifen

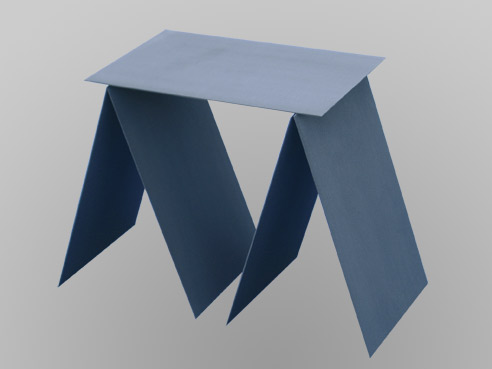

Industriekeramik sägen mit Diamantbandsägen

Materialien für Diamantbandsägen, Glas sägen, schneiden, trennschleifen

Technische Keramik Bearbeitung mit Diamantbandsägen

Technische Keramik Bearbeitung mit Diamantbandsägen

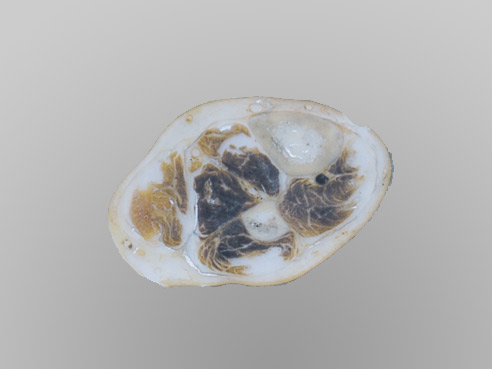

Pathologie Säge mit Diamantband

Materialien für Diamantbandsägen, Plastinate sägen, schneiden, trennschleifen, präparieren

Weitere technische Details zur Diamantsäge BS422 A – H600 FY

Die BS422-H600 FY angetriebenem Fahrständer besteht aus einer Bandeinheit mit zwei Umlenkrollen D = 420 mm und einem Durchlass (H x B) von 610 x 410 mm. Das Diamantsägeband läuft endlos über zwei Rollen. Mit der oberen Rolle, die in der Höhe verstellbar ist, wird es angetrieben und pneumatisch gespannt. Der Bandantrieb erfolgt mit einem frequenzwandlergesteuertem 3 KW Drehstrommotor. Die Bandspannung wird über den am Druckminderer einstellbaren Luftdruck eingestellt. Die Bandgeschwindigkeit ist stufenlos von 200 – 3000 m/min einstellbar.

Die Bandeinheit ist mit einer Kugelrollspindel und dem Servomotor programmgesteuert verfahrbar (X-Achse). Die Verfahrwege und Vorschubgeschwindigkeiten sind programmierbar. Die Bandeinheit kann über Taster positioniert werden. Steuerung: Mitsubishi SPS-Steuerung mit Touchscreen.

Die beim Sägen auftretende Vorschubkraft wird am Bildschirm angezeigt. So können Vorschub und Schnittgeschwindigkeit entweder manuell eingestellt oder entsprechend der programmierbaren Sollkraft automatisch geregelt werden.

Die Maschinenkabine schützt durch Plexiglasscheiben vor Spritzwasser, Geräusche und Staub. Die Kabinentüren sind zur erhöhten Sicherheit überwacht. Die Maschine schaltet sich bei geöffneter Tür ab.

Es kann im Trockenschnitt oder optional mit Kühlung gearbeitet werden. Beim Trockenschnitt wird ein Sauger an den vorgesehenen Absaugstutzen angeschlossen. Bei der rostfreien Maschinenausführung kann zur Kühlung reines Wasser ohne Zusatz verwendet werden.

| Technische Daten | Beschreibung |

|---|---|

| Länge: | 2169 mm |

| Breite: | 2001 mm |

| Höhe: | 2621 mm |

| Durchlass: | 610 mm x 410 mm |

| Verfahrweg (X, Y): | 620 mm x 420 mm |

| Umlenkrollen Ø: | 420 mm |

| Führungsrollen Ø: | 70 mm |

| Standardband: | 0,7 mm x 16 mm, Länge 3800 mm |

| Bandgeschwindigkeit: | 200 – 3000 m/min |

| Bandspannung: | 10.000 N |

| Antrieb: | Drehstrommotor 3 KW |

| Gewicht: | 550 kg |

Bandabreinigung

Bandabreinigung mit Hochdruck Spritzregister. Durch die Hochdruck-abreinigung des Sägebandes unterhalb der Bearbeitungsstelle, tritt das Band wieder sauber in den Schnitt ein.

Kühlmittelanlage mit Filtereinsatz

Auffangwanne mit Ablass in den Kühlmittelbehälter, Kühlmittelpumpe, Kühlmittelzuführung mit Absperrhahn und Gliederschlauch, automatische Ansteuerung der Kühlmittelanlage. Es kann ein ca. 0,7 x 0,7 m großes Filtervlies eingelegt und bei Bedarf ausgetauscht werden.

Zusätzliche Optionen

Kühlmittelanlage mit Filtereinsatz

Auffangwanne mit Ablass in den Kühlmittelbehälter, Kühlmittel- pumpe, Kühlmittelzuführung mit Absperrhahn, automatische Ansteuerung der Kühlmittelanlage. Es kann ein ca. 0,7x0,7m großes Filtervlies eingelegt und bei Bedarf ausgetauscht werden.

Kühlmittelanlage mit Tiefbettbandfilter

Auffangwanne mit Auslass in den Tiefbettbandfilter, Filtervliesrolle auf Transportwalze, Tiefbettbandfilter mit Sammelbehälter, Kühlmittelpumpe, Kühlmittelzuführung mit Absperrhahn, automatische Ansteuerung der Kühlmittelanlage.

Kühlmittelsystem Frischwasserzufuhr

Beim Schneiden von Silizium, da Silizium nur ungenügend gefiltert werden kann. Dies führt zur starken Verunreinigung des Kühlwassers. Frischwasserverbrauch ca. 2-5l/min.

NIRO-Version Rostfreie Ausführung

Träger und Bleche der Maschine und der Kühlmittelanlage aus Aluminium oder Edelstahl, Wellen und Lager aus Edelstahl. Bei dieser Ausführung kann reines Wasser ohne Zusatz verwendet werden.

Bandabreinigung

Kühlmittel-Hochdruckpumpe, Zuleitung, Düse zur Bandab reinigung.

Linienlaser

Linienlaser zum Anzeigen der Schnittlinie

Spritzschutzkabine Verriegelung

Während des Schneidprozesses wird die Kabine automatisch verriegelt.

GMst

Glasmaßstäbe zur präzisen Tischpositionierung.

5380

Starkstromsteckdose zum Anschluss und zur automatischen Ansteuerung einer Absaugung

Zusätzliche Optionen

Kühlmittelanlage mit Filtereinsatz

Auffangwanne mit Ablass in den Kühlmittelbehälter, Kühlmittel- pumpe, Kühlmittelzuführung mit Absperrhahn, automatische Ansteuerung der Kühlmittelanlage. Es kann ein ca. 0,7x0,7m großes Filtervlies eingelegt und bei Bedarf ausgetauscht werden.

Kühlmittelanlage mit Tiefbettbandfilter

Auffangwanne mit Auslass in den Tiefbettbandfilter, Filtervliesrolle auf Transportwalze, Tiefbettbandfilter mit Sammelbehälter, Kühlmittelpumpe, Kühlmittelzuführung mit Absperrhahn, automatische Ansteuerung der Kühlmittelanlage.

Kühlmittelsystem Frischwasserzufuhr

Beim Schneiden von Silizium, da Silizium nur ungenügend gefiltert werden kann. Dies führt zur starken Verunreinigung des Kühlwassers. Frischwasserverbrauch ca. 2-5l/min.

NIRO-Version Rostfreie Ausführung

Träger und Bleche der Maschine und der Kühlmittelanlage aus Aluminium oder Edelstahl, Wellen und Lager aus Edelstahl. Bei dieser Ausführung kann reines Wasser ohne Zusatz verwendet werden.

Bandabreinigung

Kühlmittel-Hochdruckpumpe, Zuleitung, Düse zur Bandab reinigung.

Linienlaser

Linienlaser zum Anzeigen der Schnittlinie

Spritzschutzkabine Verriegelung

Während des Schneidprozesses wird die Kabine automatisch verriegelt.

GMst

Glasmaßstäbe zur präzisen Tischpositionierung.

5380

Starkstromsteckdose zum Anschluss und zur automatischen Ansteuerung einer Absaugung